The filtering cartridges are made of the industry’s smallest nanofibre (10 microns) – the best in its class, with MERV 15 efficiency on sub-micron particles. This incredible technology is capable of capturing 100% of foreign particulates down to 0.3 µM in size and obtaining unequaled surface loading capabilities with nano-sized interfibre pores. The fibres of a conventional cartridge media are six times larger, which allows small particles to become deeply embedded within the media substrate.

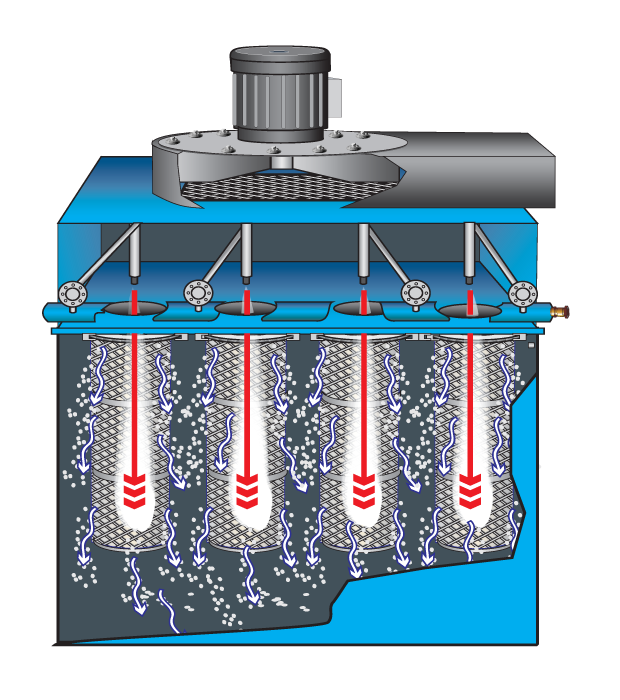

The vertical design of ISTblast cartridge-type dust collectors maximizes the filtration efficiency of these cartridges, while minimizing the maintenance required on horizontal design cartridges. Indeed, cartridges mounted horizontally lose up to 30% of their filtration capabilities due to dust accretion in the bottom cavity of the media, and for this reason, horizontally-mounted cartridges must be rotated periodically in order to maximize their performance and durability. This is not the case for vertically-mounted cartridges, since they allow dust to fall freely to the bottom of the dust collector without altering their filtering efficiency.

Dust Collector Cartridge Filter Cleaning

The cartridges are cleaned by a pulse of compressed air blowing inside. The reverse pulse momentarily halts the air flow passing through the cartridges in order to remove dust on the outer surface, and the dust then falls to the bottom of the barrel.

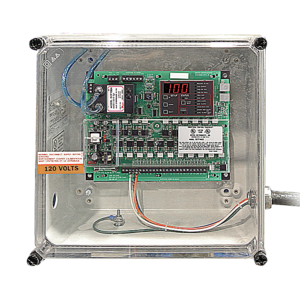

The pulse intervals are controlled by the DCT1000 Sequential Controller, which collects and compares static pressure data on both the dirty and clean sides of the filters simultaneously. When the pressure loss falls out of the predefined limit, the system generates pulses inside the cartridges until the pressure loss is within an acceptable interval.

When the sequential controller is no longer able to stabilize the static pressure, it is time to replace the filter cartridges. Unlike conventional cartridges found on the market, it is not necessary to clean them – the dust builds up only on their surface rather than deeply inside the substrate, so it releases easily upon the pulse. Also, replacing the cartridges is fairly easy – it can be accomplished without tools, from outside the dust collector’s housing.