Batch-Type Solvent Recyclers

SR Series Batch-Type Solvent Recyclers can perform a fully automated distillation processes every six hours and they are available in tank capacities of 30, 60, 120, 180 and 240 liters.

SR Series Batch-Type Solvent Recyclers can perform a fully automated distillation processes every six hours and they are available in tank capacities of 30, 60, 120, 180 and 240 liters.

Home > Solvent Distillation Systems > Batch-Type Solvent Recyclers

Durable: Built with robust, corrosion-free stainless-steel tanks.

Virtually Maintenance-Free: Require low maintenance and supervision, a simple 4-hour maintenance routine every 2,000 hours of operation.

Certified in North America: Certified to UL standard 2208 and CSA C22.2 No. 30 in Canada and the U.S. for class I, Div.1, Group D hazardous locations, and meets NFPA codes 30, 33, 70.

Cost-effective: Most of our clients have achieved a return on investment (ROI) in as little as 4 to 12 months!

Fully Automated Process: Operate on a fully automated process assisted by a PLC with predetermined parameter settings and built-in alarm signals.

Guaranteed: Backed up by industry’s leading 2-year manufacturer warranty.

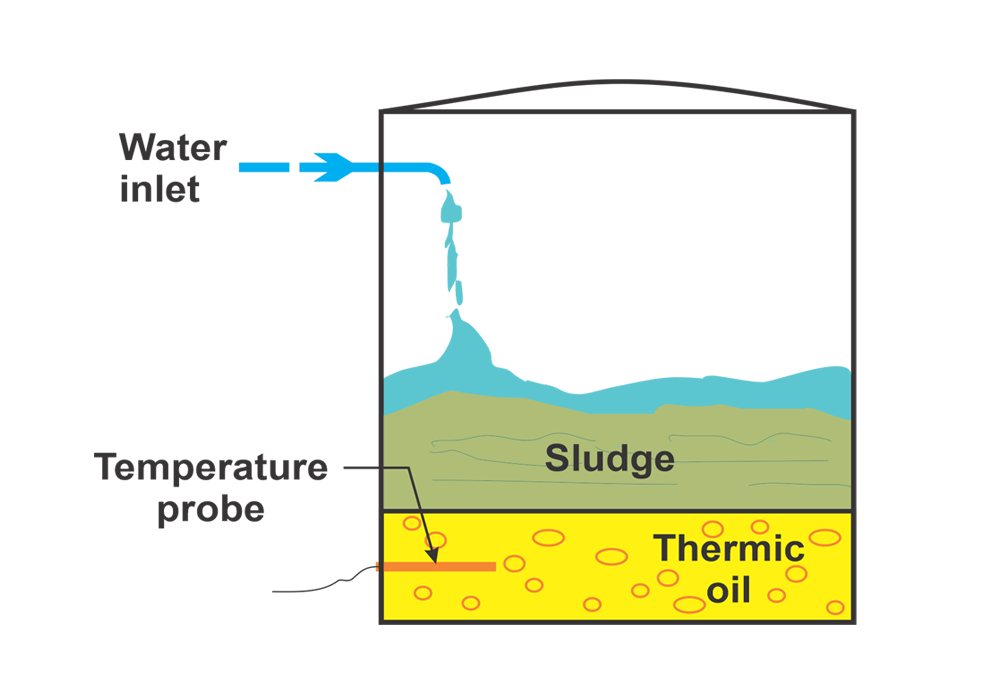

Recommended when processing highly volatile solvent, the sludge monitoring safety device would immediately shut off the heater, switch the unit to cool down, and trigger a sprinkler system inside the boiler when the sludge reaches a preset limit temperature during cycle.

Available boiler capacities of 30, 60, 120, 180 and 240 liters, each SR Series units can perform up to 4 recycling cycles per day (4-6 hours each).

Available in boiler capacities of 120, 180 or 240 liters.

Available in boiler capacities of 30 or 60 liters.

Chemical distillation column designed for high purity chemical purification

Solvent distillation units that can process up to 375 liters per hour

Welcome to our website: istsurface.com

We respect your privacy.

We use cookies to enable you to navigate efficiently and to optimize the functionality of the site. By clicking "Accept", you consent to our use of cookies. Failure to consent or withdrawing consent may have an adverse effect on certain features and functions.

"*" indicates required fields