Here are some technical documents and white papers that will help you enhance your knowledge, optimize your industrial processes, and improve your workers’ safety.

Here are some technical documents and white papers that will help you enhance your knowledge, optimize your industrial processes, and improve your workers’ safety.

Here is a comprehensive guide on sandblasting techniques, abrasive media, and equipment. Learn how to define your process parameters to obtain desired results.

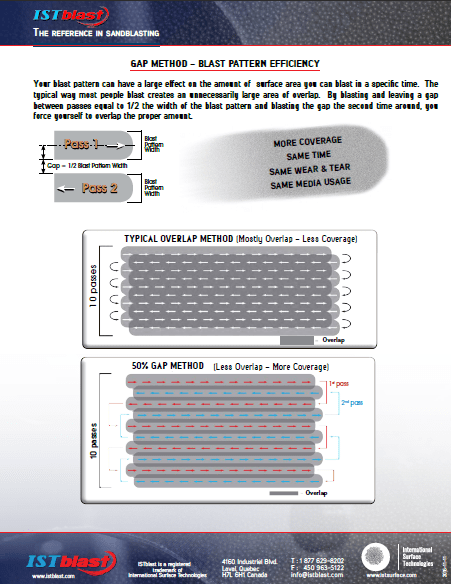

Maximize your sandblasting technique, while minimizing the process time and abrasive media consumption. The Gap Method is the ideal sandblasting pattern to cover a surface faster and without having to go over an area that is already covered.

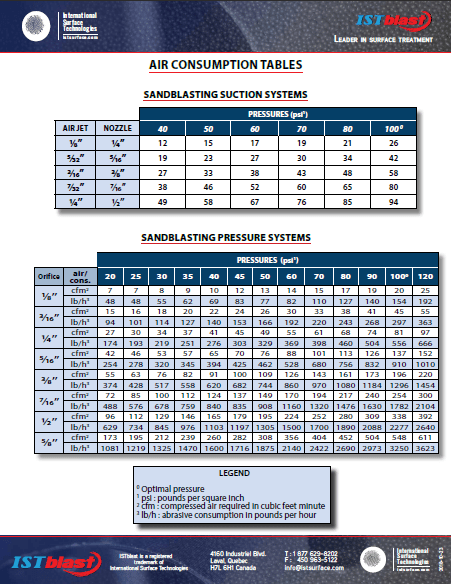

Understand the relationship between the Nozzle I.D. (interior diameter) and the Pressure Required at the Nozzle of your application in order to determine the air consumption (CFM) required from your compressor.

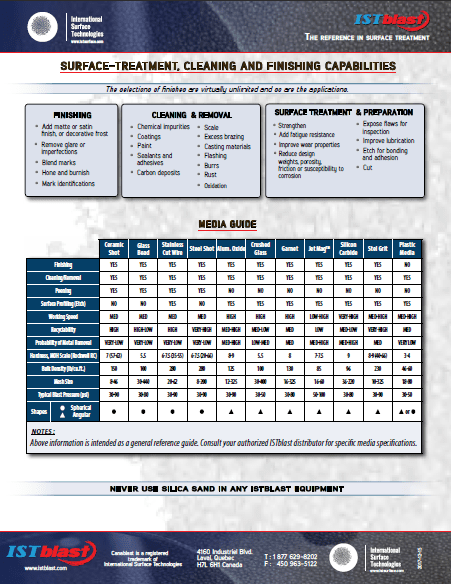

Compare the characteristics of different types of abrasive media and learn more on various applications of sandblasting.

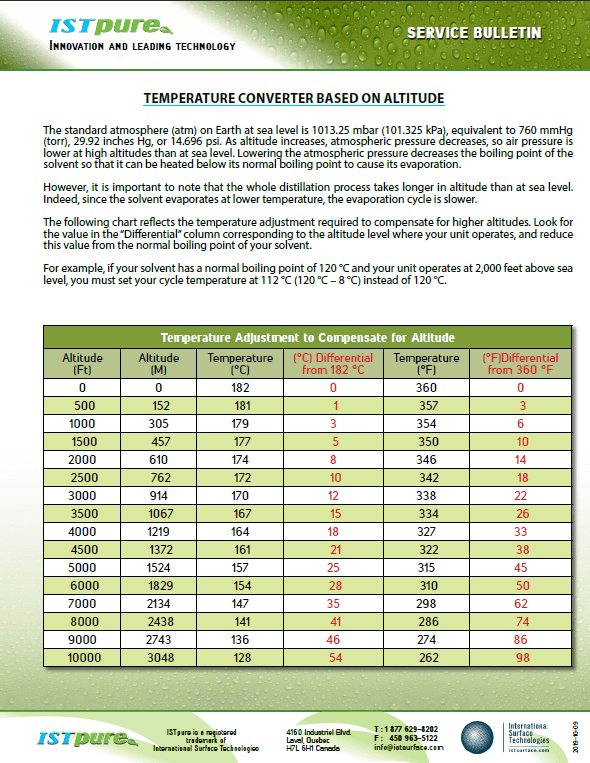

When you operate a solvent distiller in high altitude, you must adjust the temperature settings on your machine in order to compensate a lower atmospheric pressure. This guide will help you to understand this phenomenon and how to set the temperature of your process accordingly.

What is crystalline silica and what are the risks for your workers? Learn more on this mineral dust, how it affects the respiratory system, and what safety measures can be taken to protect your workers.

Master the art of sandblasting by understanding the basic parameters of the sandblasting process in order to optimize your productivity and efficiency. By controlling the basic principles, you will be able to reduce the wear and tear on your equipment as well as your abrasive media consumption while achieving the same surface treatment quality.

Welcome to our website: istsurface.com

We respect your privacy.

We use cookies to enable you to navigate efficiently and to optimize the functionality of the site. By clicking "Accept", you consent to our use of cookies. Failure to consent or withdrawing consent may have an adverse effect on certain features and functions.

"*" indicates required fields