In most blast cabinet designs, an impeller powered by an electric motor is used to draw air and dust out of the cabinet, towards the dust collector.

The impeller can be mounted onto the cabinet (on the dirty side) to push contaminated air towards the dust collector, or oppositely, on the dust collector (on the clean side) in order to suck air out of the cabinet.

The second configuration considerably increases the performance of the dust collector while extending the lifespan of the impeller.

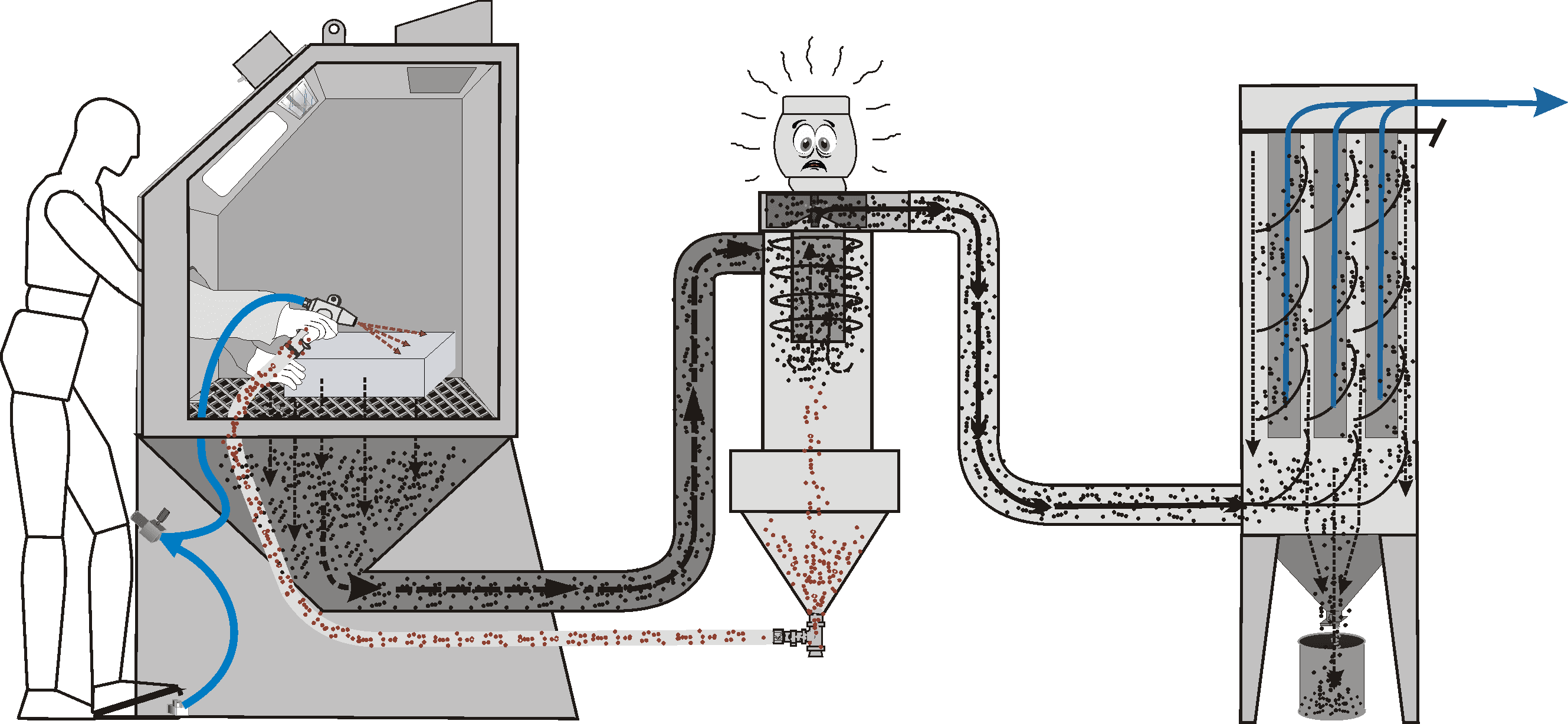

Dust Collector Impeller on the Dirty Side

When the impeller is mounted on the blast cabinet, it pushes the dust and abrasive media towards the dust collector.

However, in this configuration, contaminated air flows through the impeller, which causes premature wear on the turbine’s blades. It also limits the collector’s ability to convey dust due to airflow restriction caused by the passage through the impeller.

Therefore, we say of this configuration that the impeller is located on the ‘dirty side’ of the filter media.

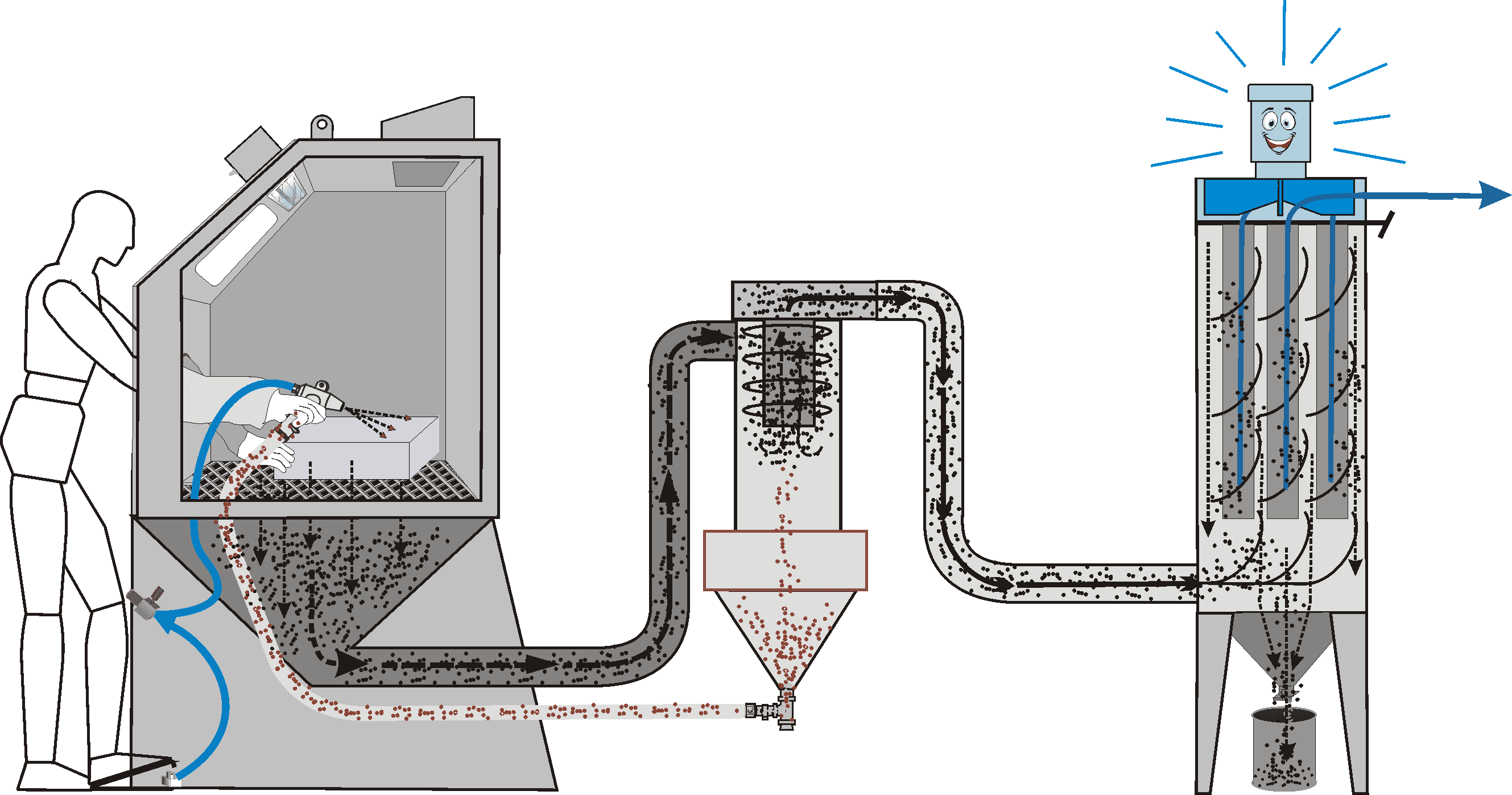

Dust Collector Impeller on the Clean Side

In an ideal configuration, the impeller is mounted on top of the dust collector and sucks air from the blast cabinet. In this configuration, the impeller is located on the ‘clean side’ of the filter media, does not conflict with proper air flow, and is never exposed to dust.

Since the turbine does not come across friction with neither dust nor abrasive media, the service life of the impeller is extended. The sucking power of the impeller is also enhanced due to the absence of restriction.

The location of the impeller on the filtration system has a significant effect on the efficiency and service life of the dust collector.