- Equipment

- Abrasive

- Parts

- Services

- Industries

- Resources

- Videos

- About

- Contact

- FR

Home > Shop > Industrial Washers > Parts Washers > SMW Series – Solvent Manual Washing Cabinet

SMW Series Solvent Manual Washing Cabinet is the most cutting-edge cleaning system available on the market today. These cabinets offer increased operator comfort with ergonomic working height and easy operation and maintenance, providing safe work environments for manually washing parts of different sizes using cleaning solvent.

Advantages of this system:

SMW Series Solvent Washing Cabinets are made of durable stainless steel and are fitted with explosion-proof components that comply with Class I Div. 1 standard. Pneumatic system circulates washing fluid in a loop and can be reused over and over. Circulating debris is trapped in pump’s integrated filtration system. Optional clean-rinse system can be added for optimal washing results.

This line of cleaning cabinets is available in different sizes and configurations to achieve desired performance for washing parts of any shape and size, without using abrasives that could damage precision-machined parts.

Choose from 3 feeding systems according to desired result and application:

High-pressure jet system powered by piston pump pushes cleaning fluid towards cleaning accessories with pressure ranging from 100 to 1,200 psi. Cleaning accessories are manually activated by pressing a trigger or flipping a switch.

Low-pressure jet system is similar to high-pressure, but uses diaphragm pump that achieves 30 to 100 psi.

Contrary to pressure jet systems, suction-type vaporization systems operate using the Venturi principle, sucking fluid from cleaning accessories. Liquid output is wide spray jet that covers large section of part that needs cleaning, and air is added to dislodge hard-to-remove oil and grease. Cleaning accessories are activated with foot treadle.

HOW IT WORKS

Various cleaning accessories and jet nozzles can be added according to application.

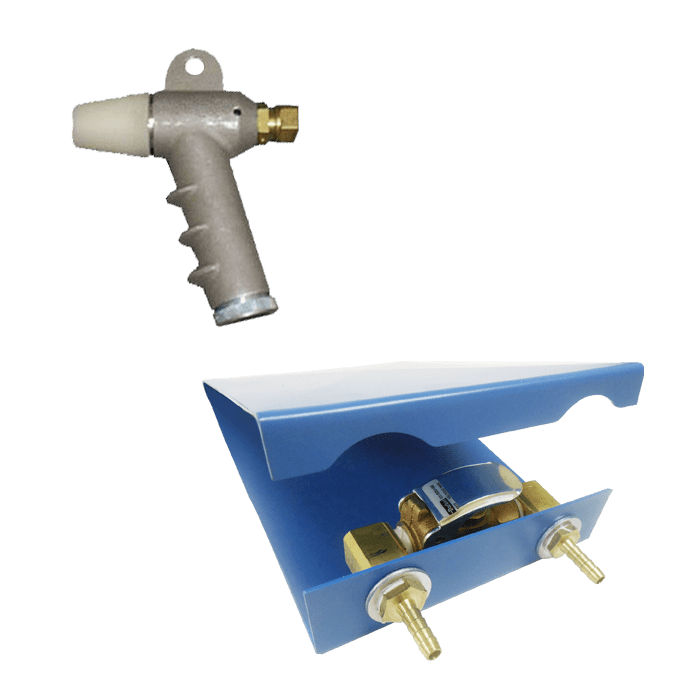

Trigger Spray Gun |

Air Blow Gun |

Precision Manual Flow-Through Brush |

Suction-Type Spray Gun Activated by Treadle* |

*Available with Suction-Type Vaporization System only

Splash |

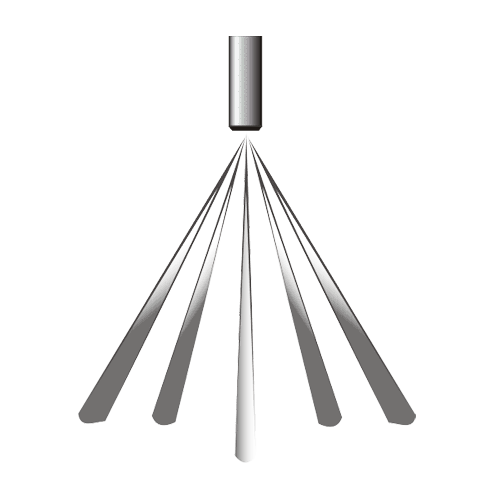

Multiple Stream |

Flat |

Hollow Cone |

Full Cone |

Square |

STANDARD FEATURES

OPTIONAL FEATURES

Manual Parts Washing Cabinet (ISTpure)

Welcome to our website: istsurface.com

We respect your privacy.

We use cookies to enable you to navigate efficiently and to optimize the functionality of the site. By clicking "Accept", you consent to our use of cookies. Failure to consent or withdrawing consent may have an adverse effect on certain features and functions.

"*" indicates required fields