- Equipment

- Abrasive

- Parts

- Services

- Industries

- Resources

- Videos

- About

- Contact

- FR

Home > Shop > Sandblasting Equipment > Automated Sandblasting Systems > Inline Basket Blaster

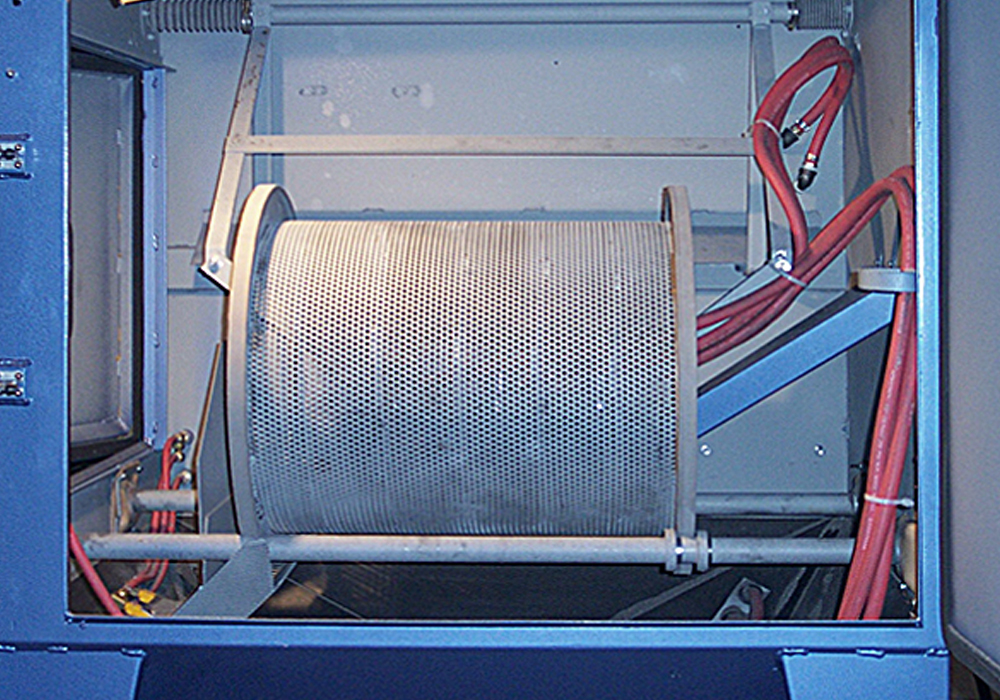

Inline Basket Blasters combines the effectiveness of a manual-fed basket blaster with the addition of an inline feeder allowing the etching or prepping of tumbling parts without any interruptions.

Simply load the parts into the feeder and collect perfectly clean parts as they exit the perforated tumbling basket on the opposite side. The basket is shaped with a shaftless screw conveyor flight all around to keep parts separated from one another and to move them towards the exit chute.

As parts travel through the rotating basket, they tumble to ensure all surfaces are being exposed to the blast stream.

The speed of traveling and exposure to the blast stream can be controlled by varying the basket’s rotation speed. The stand-off distance from the workpiece and the blasting pressure can also be adjusted to obtain the desired finish.

Parts can be loaded manually or automatically with the addition of a conveyor and/or a robotic arm.

Welcome to our website: istsurface.com

We respect your privacy.

We use cookies to enable you to navigate efficiently and to optimize the functionality of the site. By clicking "Accept", you consent to our use of cookies. Failure to consent or withdrawing consent may have an adverse effect on certain features and functions.

"*" indicates required fields