- Equipment

- Abrasive

- Parts

- Services

- Industries

- Resources

- Videos

- About

- Contact

- FR

Home > Shop > Sandblasting Equipment > Automated Sandblasting Systems > Basket Blaster

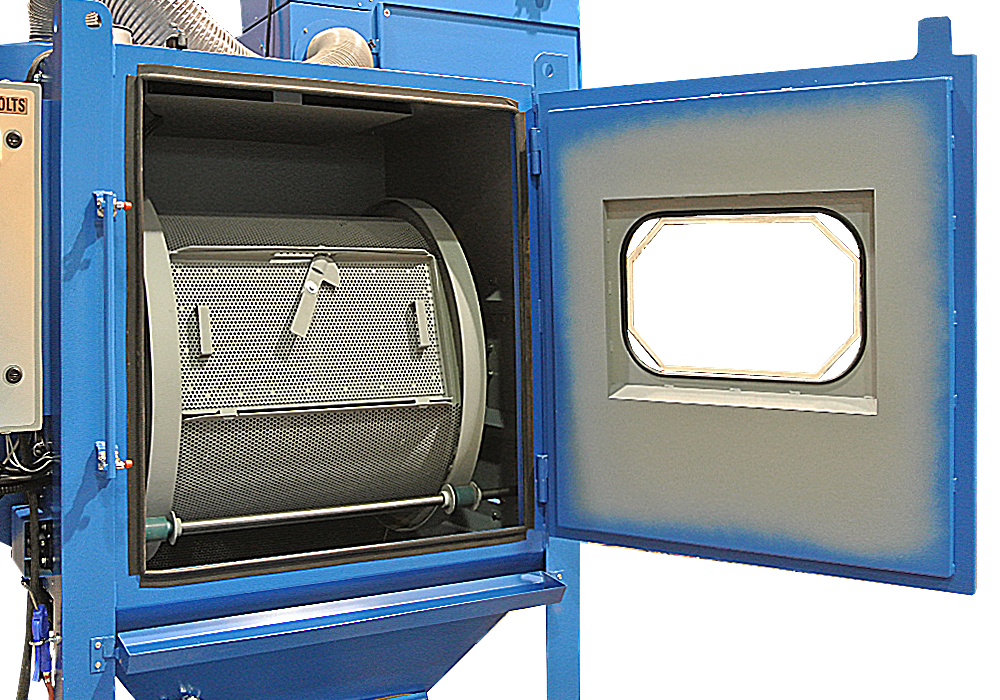

MBB Basket Blasters automate the cleaning, peening, and finishing of small workpieces. With certain types of parts, no other finishing method can compare to these heavy-duty machines in terms of speed and quality results.

Simply load the parts into the perforated tumbling basket, set the precision timer according to the desired output, and let the Basket Blaster do the rest. By tumbling the parts within abrasive blast streams, these machines deliver consistent finishes automatically.

| Basket Dimensions (Width X Diameter) |

Working Capacity | Max Load Capacity |

|---|---|---|

| 16″ X 30″ | 1½ cu. ft. | 250 lb |

| 30″ X 30″ | 3½ cu. ft. | 350 lb |

Welcome to our website: istsurface.com

We respect your privacy.

We use cookies to enable you to navigate efficiently and to optimize the functionality of the site. By clicking "Accept", you consent to our use of cookies. Failure to consent or withdrawing consent may have an adverse effect on certain features and functions.

"*" indicates required fields