Typically, there are two main types of blast cabinet delivery systems: suction and pressure. A pressure blast system will always deliver more performance than a suction blast system. However, there are other factors to take into consideration – the frequency and the duration of blasting operations per day, the budget, the availability of compressed air, and the objective of the blasting process (occasional maintenance jobs or large output volume applications?).

As they both provide valuable advantages over one another, understanding their differences is critical in order to make the right decision when purchasing your sandblast cabinet. After all, the delivery system could positively or negatively impact your process performance and overall operation costs.

Remember that the majority of blast cabinets sold today use a suction system because it still delivers a good performance with a lower overall operation/maintenance cost.

Here is a comprehensive guide demonstrating the pros and cons of both delivery systems.

SUCTION BLAST CABINET

Suction-type blast cabinets are economical solutions which are suitable for most applications that do not require a high productivity yield. These are the ideal blast cabinets for low-production operations, light-duty cleaning, and occasional maintenance jobs.

The acquisition and operation costs of a suction blast cabinet are a fraction of the price of a pressure blast cabinet. Suction blast cabinets also allow for uninterrupted blasting operations, as long as there is abrasive media left at the bottom of the cabinet.

However, suction-type blast cabinets have limits in regards to the type of abrasive media they can handle. Very heavy blasting media (larger steel media) cannot be conveyed into the air stream with suction blasting. Also, suction systems are usually outperformed by pressure-type blast cabinets for aggressive blasting operations and large-volume applications.

Nonetheless, most industrial blast cabinets use suction systems due to their lower cost and because they work well for most applications.

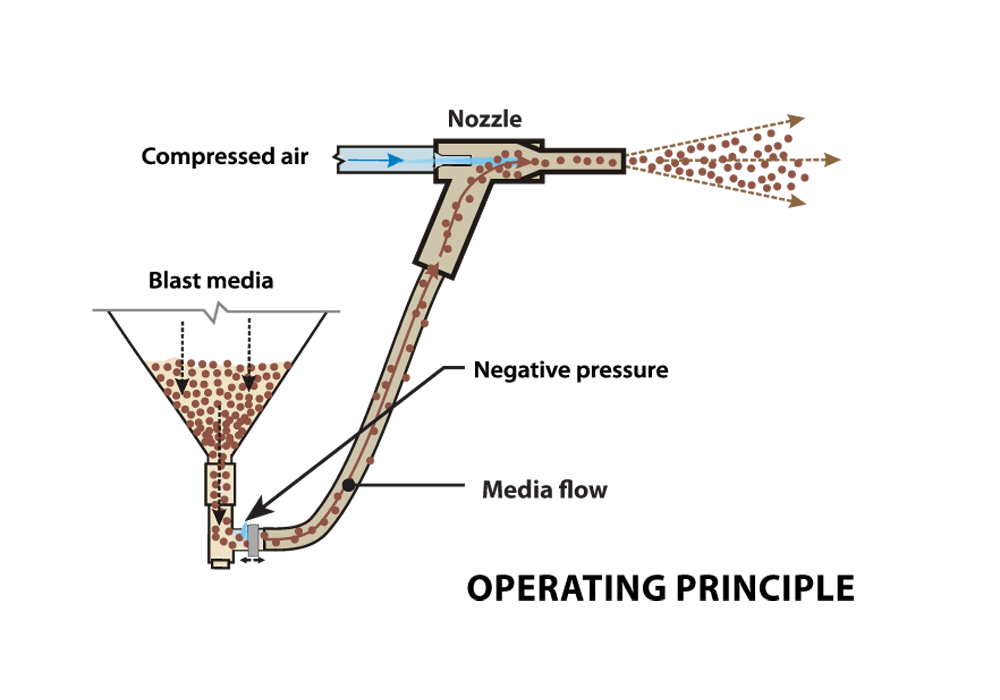

Working Principle

A suction delivery system uses the Venturi principle of sucking media from a hopper. It consists of two distinct hoses linked to the blast gun – one sucking the air through the sandblast gun, and the other carrying the media.

When the system is in operation, compressed air (released by a foot pedal or trigger gun) enters the gun and creates a vacuum which draws and expels abrasive onto the workpiece. The air jet diameter is half of the nozzle’s interior diameter and, as the air stream passes through both, this creates suction which pulls the media from the hopper into the air stream.

The media acceleration distance from the nozzle to the workpiece is short (approximately 4 to 14 inches). The suction system works fine and can continuously blast as long as there is blasting media in the hopper. This system feeds in from the bottom of the cabinet in a closed loop.

Pros of Suction Blast Cabinets

- Lower initial cost – The initial cost of a suction blast cabinet is a fraction of the price of a pressure blast cabinet. It also requires a less powerful compressor.

- Lower maintenance – The components of a suction blast cabinet wear out more slowly than those of a pressure blast cabinet due to lower friction (media flowing at a lower velocity, and the fact that highly abrasive media such as steel grit is not advised in a suction system).

- Uses less compressed air – Less compressed air is required for suction blasting with a given nozzle I.D. size, and 100% of the compressed air is used to suck abrasive media so there is no significant loss.

- Ongoing blasting operations – As long as there is blast media at the bottom of the cabinet, the suction system will feed in and propel abrasive media in a closed loop system.

Cons of Suction Blast Cabinets

- Less aggressive blasting operation – The media stream flows at a lower velocity, so the impact of the media on the work part is less aggressive.

- Less media coverage – Due to a lower velocity blast stream, the nozzle must be held closer to the work piece, resulting in a narrow blast stream.

- Slower cleaning rate – As a result of a lower velocity blast stream and shorter distance between the nozzle and the work part, the cleaning rate and productivity is obviously affected.

- Cannot propel heavy blast media – The Venturi principle has a certain sucking limit and is not suitable for propelling heavier blast media such as steel grit and steel shot, which are usually preferred for large-volume applications and anchoring patterns on hard metals.

PRESSURE BLAST CABINET

Pressure blast cabinets are much more powerful than suction systems and provide faster cleaning rates (up to four times faster). They are advised for large-volume applications and aggressive blast cleaning. The reason for this is that they use a pressure vessel to force media through the blasting nozzle at a much higher velocity than a suction system. Also, the nozzle is used at its full potential, without any restriction caused by the air injector where the opening is usually half of the size of the nozzle.

The acquisition cost of a pressure blast cabinet is higher than that of a suction blast cabinet due to the addition of several other components specific to this system – including a pressure vessel, a metering valve, a manifold, and heavy-duty components able to withstand high-velocity abrasive media friction. It also requires more supervision and maintenance because the components wear out more quickly.

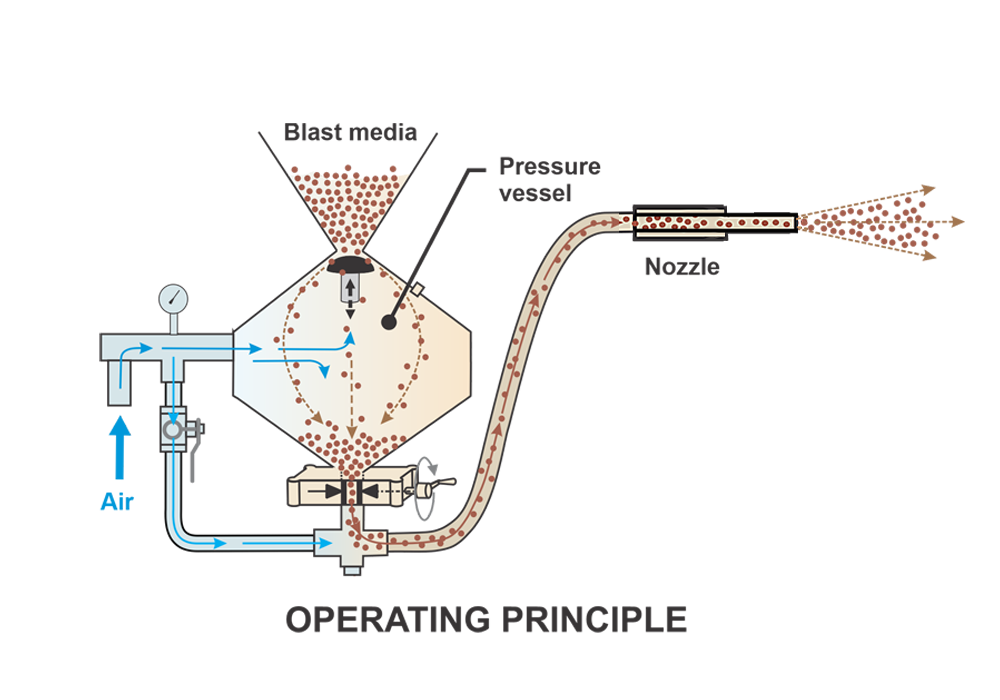

Working Principle

In a pressure blast cabinet, a pressure vessel (pressure pot) is used to store a quantity of blast media at high pressure. When the air/media mix is released from the pot, it accelerates through at least 5-10 feet of hose, then picks up even more speed as it travels through the Venturi of the nozzle.

The acceleration rates of the air/media mix are much higher in pressure blasting than in suction blasting, resulting in both a more aggressive impact on the workpiece and a faster cleaning rate. Pressure blasting operations are usually controlled by a foot pedal, and the abrasive metering valve is used to obtain the ideal air/media mix to maximize impact onto the workpiece while keeping media consumption at its minimum.

Once the pressure pot runs out of media, it must be depressurized in order to refill its tank. A storage hopper is usually mounted on top of the pressure pot to store a reserve of media which automatically falls down the pressure tank when its pressure is released. Nevertheless, pressure blasting necessarily results in interrupted blasting operations each time the pressure vessel is empty (it takes approximately 1-2 minutes to refill).

Pros of Pressure Blast Cabinets

- Greater media velocity – The key advantage of the pressure delivery system is its capacity to propel media at an extremely high velocity compared to the suction system.

- Increased productivity – Whether you are cleaning a part or anchoring a pattern prior to a coating job, a pressure blast cabinet will always allow for a significant increase in the productivity of the blaster. Achieving the same result with a suction system (when it is possible to achieve), will require more time, passages, and/or abrasive media.

- Faster cleaning rate – For blast cleaning applications, a pressure system will allow the use of a more aggressive blasting material, moving the blast nozzle faster over the part, and an increase in the standoff distance between the nozzle and the part. Increasing the standoff distance produces a wider blast pattern while maintaining a velocity great enough to correctly impact the workpiece. Again, this results in higher productivity, cleaning rates, and/or any other goals you are trying to achieve.

- More aggressive blasting operation – Some applications will only work with a pressure delivery system, such as stripping powder coat and removing tough contaminants. For these applications, a suction system would either not be able to do the job, or it would take the blaster a significant amount of time and abrasive media to accomplish the task.

- Moves more media – More velocity means that the pressure system also delivers a greater quantity of media onto the workpiece at a given time. This also plays in favour of the faster cleaning rate a pressure system can achieve over a suction system.

- Can handle any types of media – The pressure blast system has no restrictions when it comes to the types of abrasive media it can propel – including heavy steel grit or shot.

Cons of Pressure Blast Cabinets

- Higher initial cost – The major downside of a pressure blast cabinet is the initial cost, which is significantly higher than a suction blast cabinet. However, the additional investment is usually recovered quicker when considering the cost of labour and increased productivity.

- Requires more maintenance – The components wear out faster than those of a a suction-type blast cabinet due to the friction caused by high-velocity media passage – especially the blast nozzle, blast gloves, and media-conveying hose.

- Requires more compressed air – A pressure system requires more air than a suction system for a given nozzle ID and blast pressure. Pressure blast systems require a minimum of 25 psig to operate and consume more air in order to maintain the pressure. Air is lost every time the pressure pot pressurizes and depressurizes, while in a suction system, nearly 100% of the compressed air is driven into the media stream.

- Interrupted blasting operations – The blasting autonomy is linked to the size of the pressure pot. At IST, we use a 1.3 cu.ft. pressure vessel which provides approximately 12 minutes of continuous blasting operations, after which the operator will need to wait 1-2 minute(s) for the pressure tank to refill with abrasive media.

- Quick degradation of soft media – With such a high blasting performance, soft media with low recycling rates will deteriorate very quickly, resulting in higher abrasive consumption. Using hard metal abrasive is usually advised in order to take full advantage of a blast system while also maintaining decent media consumption.

CAN A SUCTION SYSTEM BE CONVERTED INTO A PRESSURE SYSTEM?

The short answer is yes. However, the conversion involves a lot of work, time, and money, so you might as well select the right delivery method as you purchase the cabinet for the first time.

Nonetheless, here is an overview of how a suction-to-pressure conversion would look: Guide to Converting a Suction System into a Pressure Blast System.