If you are unfamiliar with how the pressurization/depressurization of the blast pot works, we suggest you read the guide How to Operate A Pressure Pot Sandblaster.

You can choose between three configurations when you purchase a PPB Series Pressure Sandblaster, each of which have benefits for a given application.

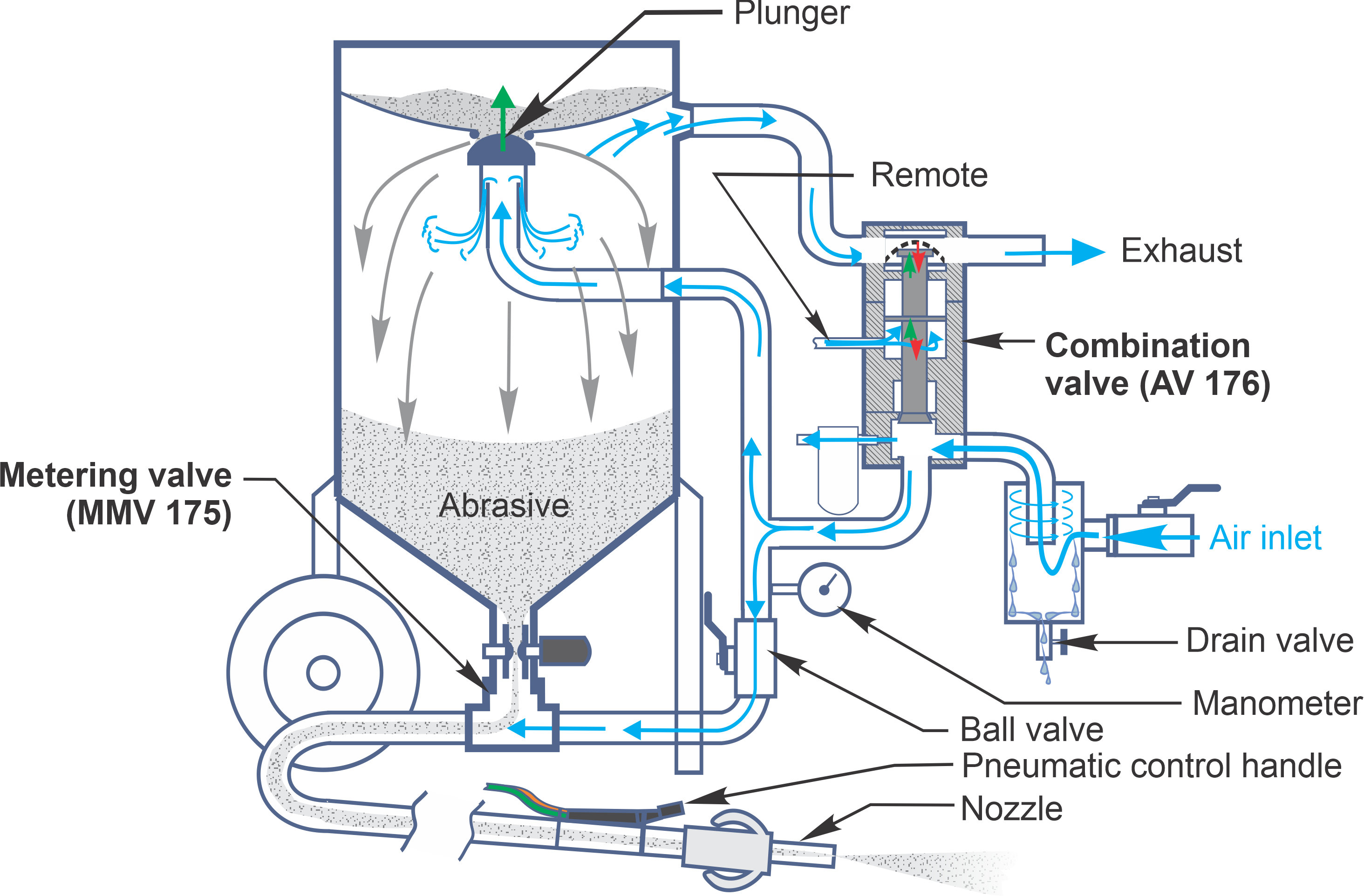

RC-176 PRESSURE RELEASE SYSTEM

The RC-176 Pressure Release System extends blasting autonomy by automatically filling the tank while the machine is on standby.

Advantages

- Autofill Function – The pressure vessel automatically depressurizes and fills up each time the remote control is released.

Long-Lasting Abrasive Metering Valve – Less wear-and-tear on the abrasive metering valve, since it is a normally open valve and not actuated. - Simplified and cheaper maintenance – The AV176 Combo Valve is a robust piston-activated valve that does not require much attention if used correctly.

Disadvantages

- Air Consumption – Since the pressure vessel automatically loses its pressure each time the handle is released, it must then rebuild its pressure every time the handle is activated. This makes the compressor work a lot more to get the job done.

- Uneven Media Flow on Start – When the blaster activates the remote-control handle, the first few seconds will produce an uneven, weak media flow until the pressure is built up correctly within the vessel.

How It Works

The RC-176 Pressure Release System relies on the AV176 Combo Valve. It is called the Combo Valve because it controls two actions at a time – the compressed air supply to the pressure vessel and the push line, as well as the exhaust of air from the pressure vessel.

The AV176 Combo Valve is a normally closed valve. In its initial position, the plunger blocks the supply of air towards both the pressure vessel and the push line, and allows the exhaust pipe to open. When actuated, the plunger moves up and does exactly the opposite – it obstructs the pressure vessel exhaust pipe and allows the flow of compressed air through the vessel and the push line, so that the vessel can build up its pressure and the push line is supplied and ready to go.

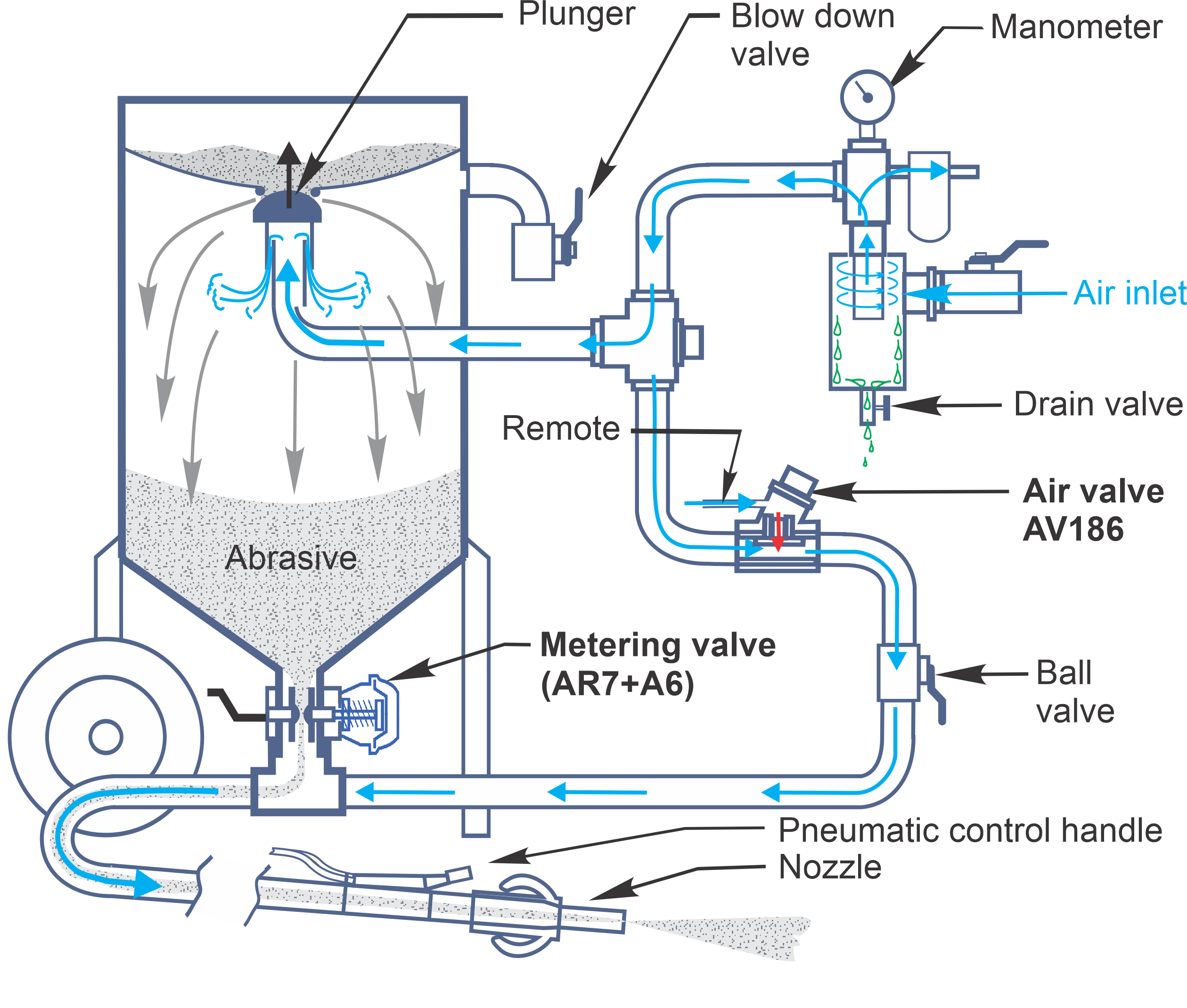

RC-186 PRESSURE HOLD SYSTEM

A Continuous Pressure System (RC-186) facilitates frequent on/off abrasive blasting operations by maintaining the pressure inside the pressure vessel.

Advantages

- Constant Pressure – When the remote-control handle is released, the pressure is maintained in the vessel and the push line is ready to blast.

- Reduced Air Consumption – Because the pressure vessel remains pressurized, nearly 100% of the compressed air produced by the compressor is used effectively.

- Even Abrasive Flow on Start – When the blaster activates the remote-control handle, the media flow exiting from the nozzle is even and effective immediately, which results in higher productivity.

- Productivity – This system is convenient for frequent start/stop operations.

Disadvantages

- Requires a Regular Maintenance Program – The Abrasive Metering Valves (AR7 or PMV-186) have some wear parts that must be replaced occasionally. The AV176 Air Valve also has a diaphragm and a few seals to be replaced from time to time, to eliminate pressure loss.

- Shorter Blasting Autonomy – Once the pressure vessel runs out of abrasive media, it must be manually depressurized in order to be refilled with media.

How It Works

The RC-186 Pressure Hold System relies on two manually-operated ball valves to control the pressurization/depressurization of the vessel – one at the air inlet and the other at the exhaust pipe. To build up pressure inside the vessel, the operator must simply open the air inlet valve and close the exhaust valve. To release the pressure, they must simply do the opposite.

Once the pressure vessel is pressurized, the sandblaster is ready to go. When the operator activates the remote-control handle, a signal is sent to activate both the AV-186 Diaphragm Air Valve and the Abrasive Metering Valve (either the AR7 or PMV-186) simultaneously. When both valves are open, the compressed air can flow through the push line, collect abrasive media during its passage, and be propelled at a high velocity through the blast nozzle.

The ball valve located between the AV-186 Air Valve and the Abrasive Metering Valve is used mainly for maintenance purposes or to shut off the push line in case the AV-186 Air Valve fails.

COMBO SYSTEM WITH A REMOTE SWITCH

The Combo System (RC-176/186) offers the same benefits of each system collectively, without the inconvenience.

Advantages

- Complete Remote Control Over the Blast Pot – Allows the operator to take full advantage of a Pressure Hold System on productivity, along with an easy means to depressurize the blast pot and refill it with media from the job site without having to walk back to the sandblaster.

- Ideal System for Remote Location – This system is particularly appreciated by operators who work a few feet away from the blast pot, in order to avoid unproductive back-and-forth movement normally required to fill up the pot when it is empty – especially in a blast booth, as it allows the operator to fill up the blast pot without the hassle of leaving the booth and taking off the safety equipment.

Disadvantages

- None!

How It Works

The RC-176/186 double control system operates similarly to an RC-176 Pressure Release System, with the addition of a switch box which interferes with the signal to let the operator control when the pressure must be released from the pressure vessel.

As long as the switch is set to “Pressurized Vessel”, the operator can control the push line and the Abrasive Metering Valve (either AR7 or PMV-186) by activating the remote-control handle. When the blast pot runs out of media, the operator must simply set the switch to “Depressurized Vessel” to release the pressure inside the blast pot, let the plunger fall, and allow abrasive media to fill up the pot.