ISTblast Robotic Sandblast Machines are designed to achieve the highest standards in surface preparation and peening applications, as well as for high-throughput production of repetitive parts.

For over 45 years, IST has provided custom-engineered, air-powered surface treatment equipment and abrasive media recovery systems for a wide range of cutting-edge industries including aerospace, military, automotive, construction, energy, and manufacturing.

Our robotic air-blast systems and computer-assisted sandblasting solutions integrate the latest servo and CNC technologies to increase productivity, precision, performance, and quality, while also minimizing overall operation and maintenance costs.

The addition of robotic arms which can be used to blast and/or handle parts results in the most advanced surface treatment system that combines agility, efficiency, precision, and reproducibility.

ADVANTAGES OF OUR ROBOTIC SANDBLASTING EQUIPMENT

- Ideal stand-off distance and blasting angle, all the time.

- Robots never get tired and never miss a spot.

- Highest possible levels of quality and reliability.

- Intuitive interface for data collection and sequence programming.

- 3D modelling of parts for a precise surface treatment.

- CAM/CAD integration with most design softwares.

HOW IT WORKS

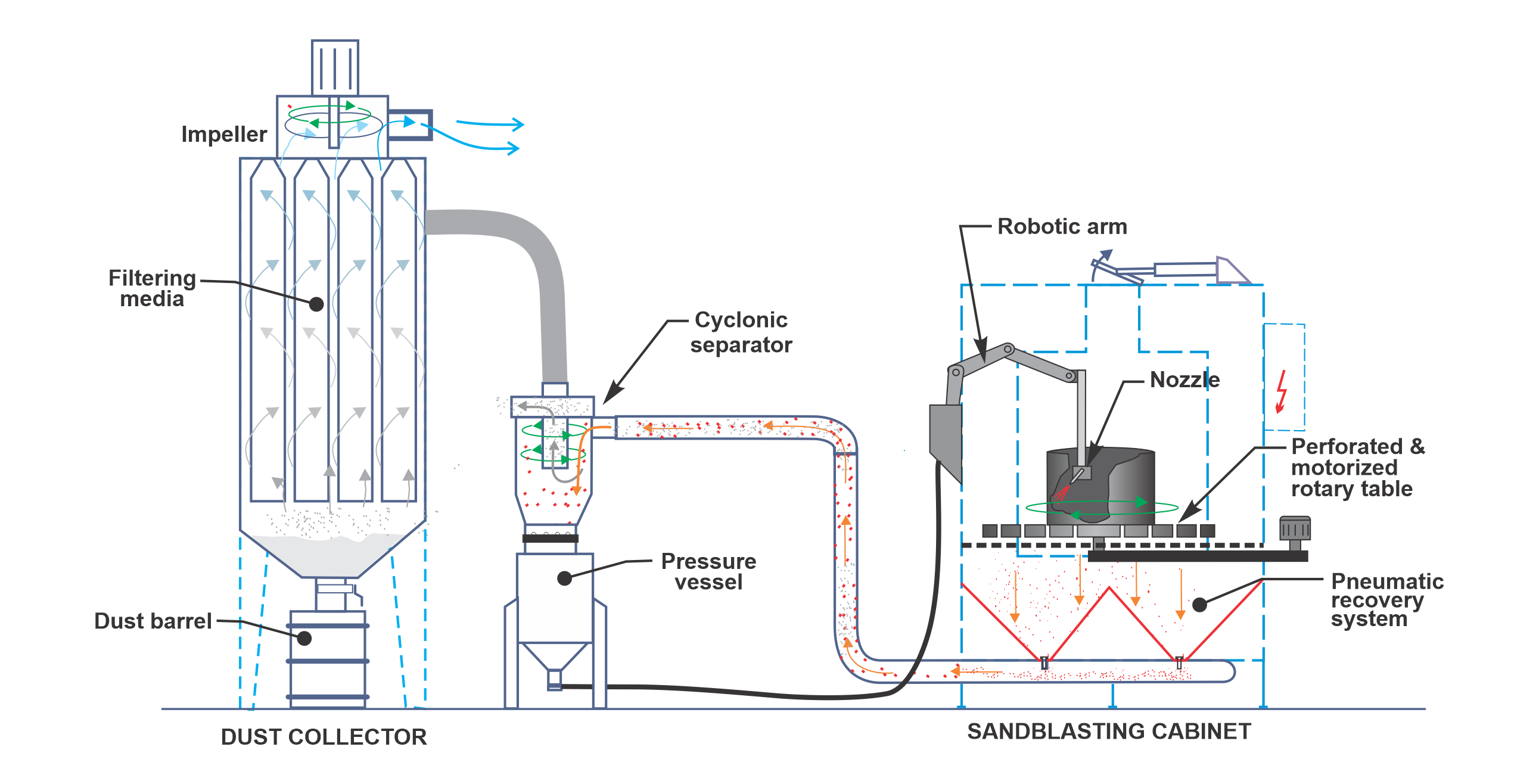

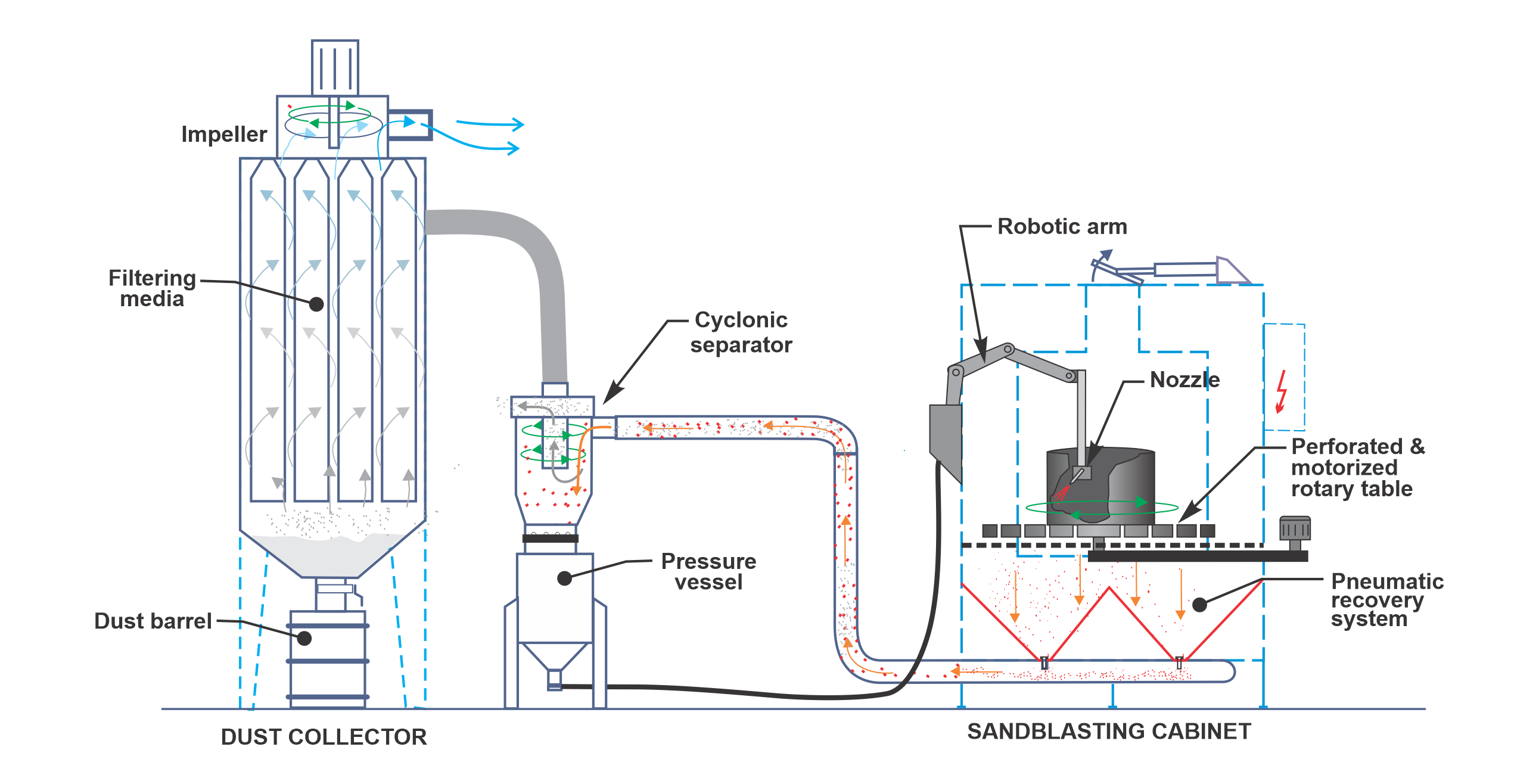

IST partners with industry leaders in robotic and automation solutions to provide the ideal sandblast system for your application and to ensure a smooth integration with your production line. The most common system combines a motorized turntable in synchronization with a 6-axis robotic arm blaster to provide the ideal stand-off distance and blasting angle. A broad range of CNC and servo systems can be incorporated to better address your application. All robotic sandblast machines are tailored to customer requirements and specifications in order to deliver optimal quality, performance, and productivity.

3D MODELLING AND SEQUENCE PROGRAMMING

Basically, you have three options to train your robot into the right blasting sequences:- Import a CAD File – The simplest way if you already own your CAD design is to import that design into the robot software interface and set the process parameters (stand-off distance from the workpiece, speed of action, etc.).

- Use a 3D Scanner – If a CAD import is not possible, a 3D scanner can be used to reproduce the part with a high level of accuracy for sequence programming.

- Teach your Robot – The longest way, but sometimes the easiest way, is to teach your robot the correct sequence by programming every movement manually.

KEY FEATURES

- Flexible Robot Control: The control box can control the 6-axis robot, along with a motorized turntable (7th axis) to master any sequences on complex parts.

- Intuitive Interface: The robot programming, monitoring, and data collection can be accomplished with the supplied control terminal, on a remote computer, or directly on the PLC equipped with a touch screen HMI.

- Custom Design and Fabrication: Each system is tailored to the customer’s specifications to address all process constraints and for optimal results and productivity.

- Personalized Process: Personalize your process by varying abrasive media, blast nozzle size, blasting pressure, table rotation speed, and blasting cycle time.

- Fully Automated Cycle: Process sequences are controlled by PLC and interfaced with an intuitive HMI touch panel.

- Baghouse Dust Collector: Choose from a range of high-efficiency baghouse dust collectors for both optimal blasting performance and minimizing wear and tear on critical components.

- Media Reclaiming System: Cyclonic separation of contaminated abrasive media for optimal performance – dust and by-products are diverted to the dust collector.

- Electricity: Available in all voltages and frequencies.

- Compliance: Design and door switches comply with OSHA requirements and most local safety jurisdictions.

- Parts Cleaning: Automatic blow-off cycle to remove all dust and contaminants from the freshly-blasted parts.

- Liner Protection: Rubber lining protection on the inner wall, rotating table, and media reclaimer for extended service life (Linatech).

OPTIONAL FEATURES

- Tower Status Indicator Lights: Stack lights offer modular stackable components that provide illuminated and audible status indication for machines, systems and process.

- Baghouse Dust Collector Optional Package: Improve your standard dust collector efficiency and performance with the addition of an automatic cleaning procedure on filter media, a vertical or horizontal muffler, and a sealed dust collection drum.

- Cartridge-Type Dust Collector Upgrade: Increase your overall process quality and efficiency with a fully-equipped cartridge dust collector able to capture up to 99.9% of particles down to 5 µm.

- HEPA Filters: Our dust collectors are designed to fit a HEPA filter when the process requires it, which can capture 99.98% of particles down to 0.3 µm.

- Parts Handling Robots: Automate tedious and unsafe parts handling tasks with a dedicated robotic arm.

- Loading/Unloading System: Facilitate the loading/unloading procedure for heavy parts while preventing injuries in the workspace.

- Remote PLC I/O: Benefit from remote access assistance on the PLC, allowing for instant troubleshooting and easy software updates.

- MagnaValve Abrasive Regulator: The MagnaValve and controller provide an accurate regulation of ferrous and non-ferrous media in shot peening and blast cleaning applications where accurate and repeatable flow rates are desired.

- SWECO Vibratory Media Classification System: The SWECO particle separation and sifting system provides an accurate media classification and sizing for precise peening or blast cleaning applications.