- Equipment

- Abrasive

- Parts

- Services

- Industries

- Resources

- Videos

- About

- Contact

- FR

Home > Shop > Dust Collection Systems > Dust Collectors for Sandblasting and Shot Blasting Equipment > DCM1000-50000 – Cartridge-Type Motorized Dust Collector for Abrasive Blast Room

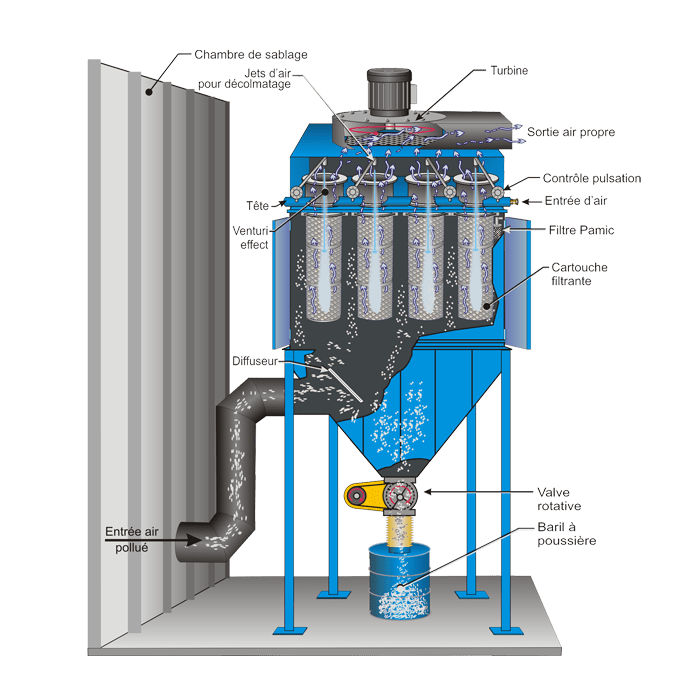

The ISTblast DCM2000 to 50000 Series dust collectors are specially designed for pneumatic or mechanical blast rooms of any sizes or treatment capacity. This line of dust collectors stands out for its ability to filter highly contaminated air volumes while remaining extremely compact.

Our cartridge media is able to capture 99.9% of particles down to 1 µm.

Modular design allows for mounting multiple units together to accommodate room size and process-extraction capacity requirements. Each unit contains between 6 and 24 cartridges and delivers performance yielding up to 50,000 CFM.

The vertical design of our dust collectors provides more efficient pulsing of dust, eliminating uneven dust loading associated with horizontally mounted cartridges. Vertical cartridge design achieves continuous 100% filtration rate.

Also, they require less attention and care since the vertical cartridges don’t require to be rotated to ensure uniform wear on all surfaces.

This DCM Series dust collector features an automatic, programmable reverse pulse cleaning system for cartridges, and a digital pressure differential indicator to monitor the deterioration of the cartridge filtering efficiency.

Thanks to reverse-pulse jet-cleaning systems, this line of cartridge-type dust collectors guarantees a dust-free work environment, contributing to increased operator productivity while minimizing equipment wear and tear.

DCM Series dust collectors include sealed mechanisms and easy-access doors, and require no tools for changing filter cartridges. Automatic self-agitating system removes dust agglomerated on cartridges without any intervention.

The cartridge replacement process is effortless and accessible by the front door. The operation and the cleaning process of the dust collector are fully automated and controlled by the sandblast booth PLC.

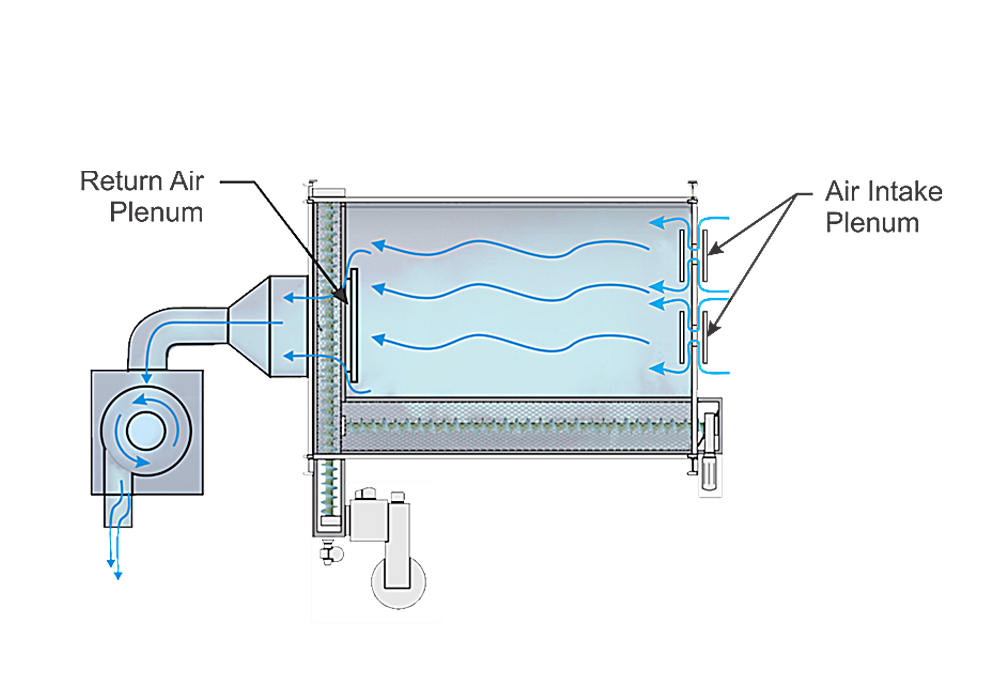

The main access door is usually fitted with two air inlet plenums and the opposite wall has two outlet plenums to allow even air circulation from one end to the other end of the abrasive blast room.

Air inlet and outlet plenums are equipped with adjustable deflectors to maintain a well-balanced airflow inside the sandblasting booth. Airborne contaminants travel through a duct work linking the outlet plenums to the dust collector, where it can be collected into a dust barrel.

Air inlet and outlet plenums are equipped with adjustable deflectors to maintain a well-balanced airflow inside the sandblasting booth. Airborne contaminants travel through a duct work linking the outlet plenums to the dust collector, where it can be collected into a dust barrel.

An even airflow provides great visibility to the blaster by drafting away the dust cloud generated from the impact of the blast media onto the workpieces and preventing premature wear on mechanical components.

HOW IT WORKS

Fast, simple and safe cartridge replacement

Cartridge replacement is performed outside dust collector and requires no tools, eliminating need to work in confined space and allowing worker to access cartridge without getting dirty. Cartridge comes with rectangular top plate that simplifies handling and eliminates potential for installation errors.

Continuous operation

Unlike other types of dust collectors such as bag shakers, cartridge dust collectors do not have to be stopped in order to remove and clean dust particles from filters. Process occurs continuously and automatically.

Economical

The cartridge dust collector is an economical choice because it requires minimal maintenance: only periodic cartridge replacement is necessary. Replacement frequency depends on application and usage.

Technical features:

Welcome to our website: istsurface.com

We respect your privacy.

We use cookies to enable you to navigate efficiently and to optimize the functionality of the site. By clicking "Accept", you consent to our use of cookies. Failure to consent or withdrawing consent may have an adverse effect on certain features and functions.

"*" indicates required fields