- Equipment

- Abrasive

- Parts

- Services

- Industries

- Resources

- Videos

- About

- Contact

- FR

Home > Shop > Sandblasting Equipment > Sandblasting Booths > MRS500 Vacuum Recovery System

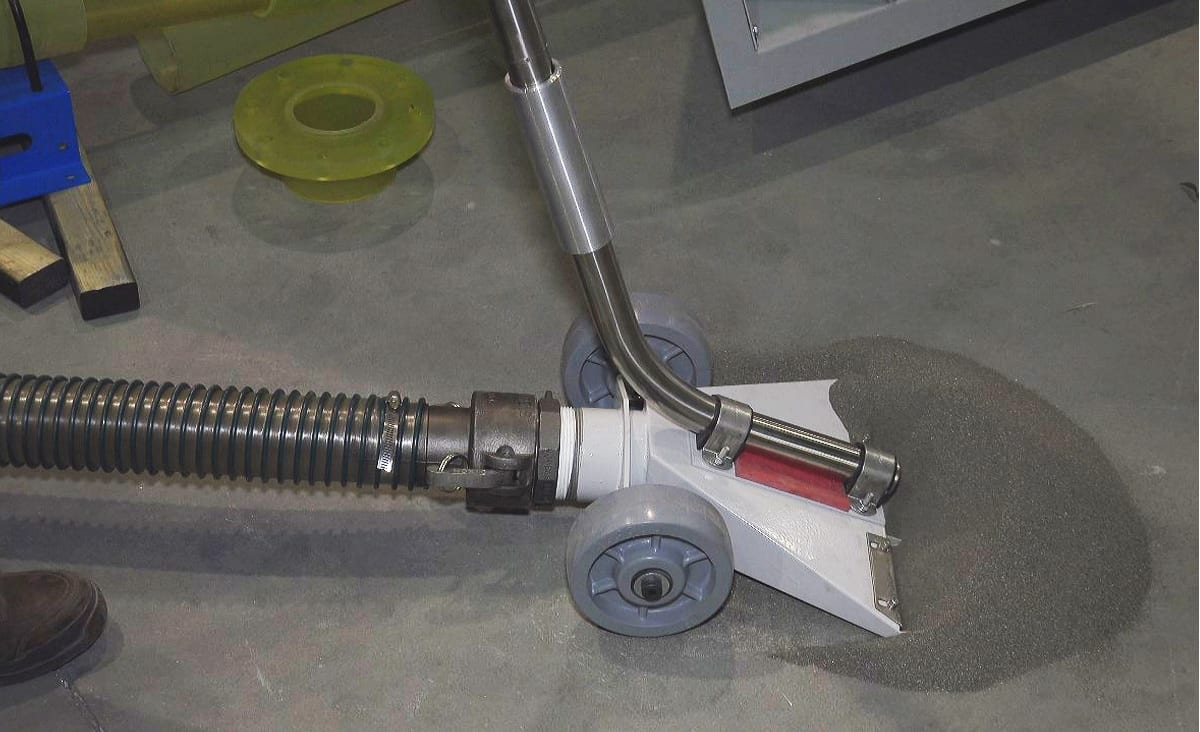

The MRS500 Vacuum Recovery System uses a vacuum head to suck in residual abrasive from large tanks and hard-to-spill reservoirs. This system does not use floor hoppers, which requires less care and maintenance and makes it very inexpensive and easy to implement.

This solution is designed specifically for applications where residual abrasive media is confined in cavities or cannot be “economically” shovelled into recovery hoppers. Otherwise, the floor-cleaning process using a vacuum head is counterproductive and very long to perform. For installations where excavation is not possible, we would recommend a MSW1200 or MRS200 with an above-floor installation.

MRS500 high performance Vacuum Recovery System consists of:

HOW IT WORKS

This system is delivered with a DCM200 Dust Collector which has an overall filter area of 200 sq. ft. and is equipped with a 20 hp / 400 cfm engine.

The recovery rate capacity is capped at 1,000 lb/hr due to the restriction caused by the interior diameter of the vacuum head.

Abrasive Blast Room (ISTblast)

Welcome to our website: istsurface.com

We respect your privacy.

We use cookies to enable you to navigate efficiently and to optimize the functionality of the site. By clicking "Accept", you consent to our use of cookies. Failure to consent or withdrawing consent may have an adverse effect on certain features and functions.

"*" indicates required fields