- Equipment

- Abrasive

- Parts

- Services

- Industries

- Resources

- Videos

- About

- Contact

- FR

Home > Shop > Sandblasting Equipment > Sandblasting Booths > MSW1200 Pneumatic Floor Recovery System

The MSW1200 Pneumatic Floor Recovery System is a very affordable solution with limits on the length of the recovery hoppers (max. 10 feet), and which can only convey lightweight abrasives such as glass beads, aluminum oxide of small mesh size, and GMA Garnet (heavy media like steel grit or steel shot cannot be vacuumed).

This blast recovery system is designed for light-duty applications that do not produce large contaminant pieces.

This sandblast recovery system is delivered with a DCM230 Dust Collector, which has an overall filter area of 200 sq. ft. and is equipped with a 3 hp / 1,200 cfm engine.

The recovery rate capacity is 1,500 lb/hr.

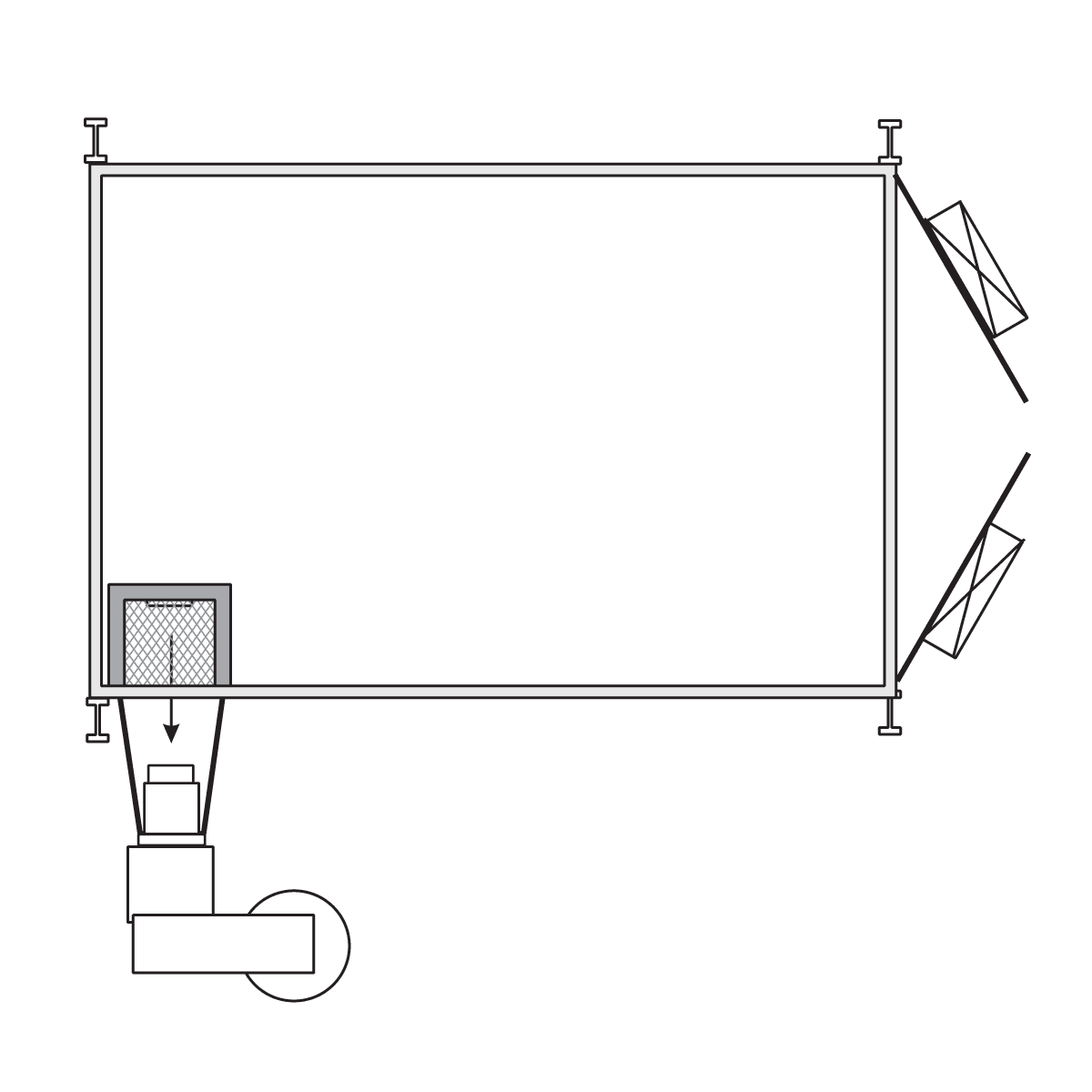

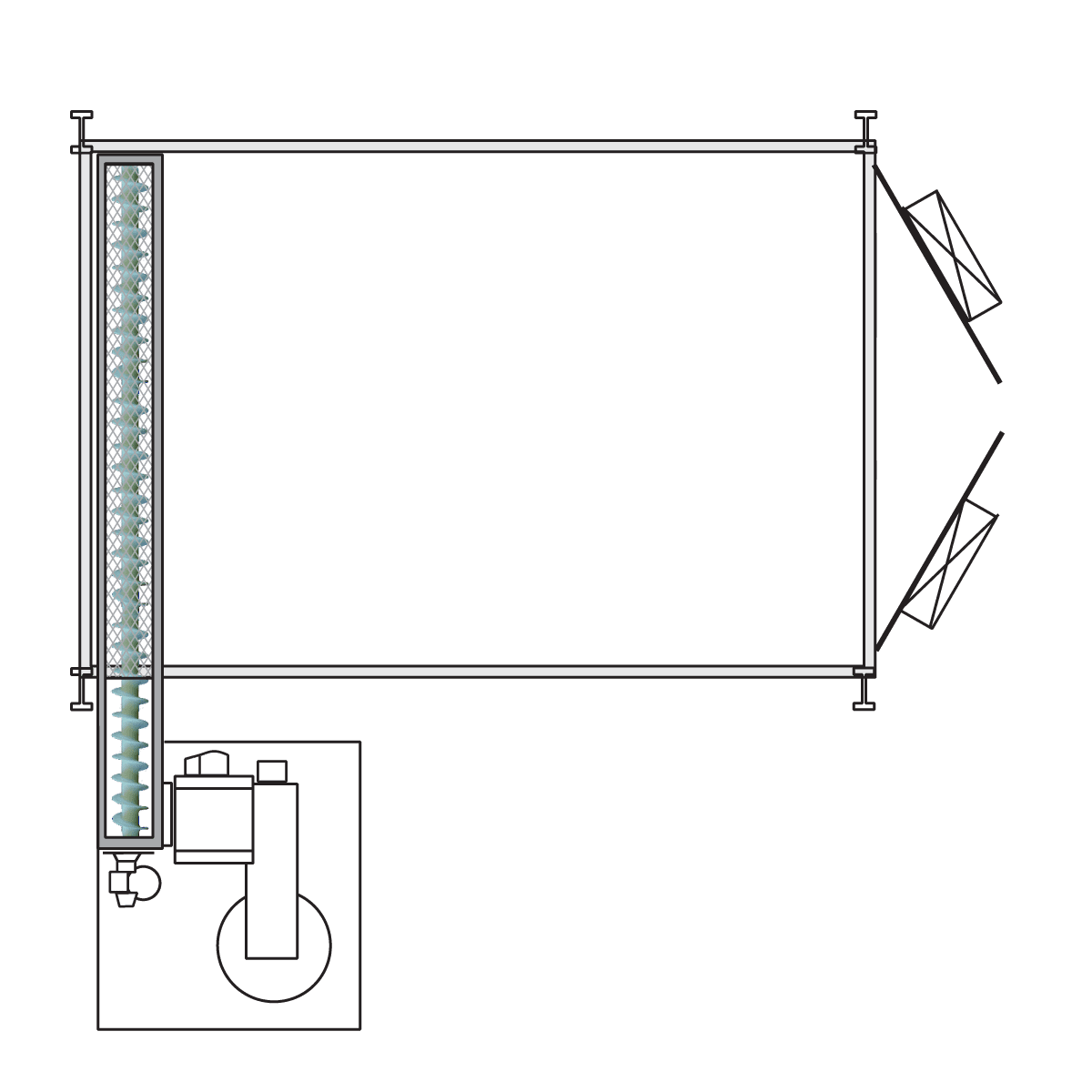

Here are the only two floor recovery hopper layouts available for this system.

|

|

| Corner Shoot | Single Pneumatic Trough (10 ft max) |

ISTblast offers various types of recovery floors that can be adapted to your production space. Either for surface or excavated installation, dimensions can vary from 4 feet in length for compact installations to maximum 10 feet for high output industrial facilities.

Shallow and space saving over-floor design is easy to install and requires limited maintenance. 17” floor excavation is sufficient for existing floors. System can also be installed on concrete floor or any other permanent or temporary floor.

We manufacture a complete line of Recovery Systems to accommodate sandblasting facility constraints, and these systems are compatible with our equipment, other manufacturers’ equipment, and even with self-made facilities. Good abrasive-recovery systems respect the 3R fundamentals: Recover, Recycle, Reuse.

Recycling abrasives results in substantial savings in abrasive consumption while protecting the environment from harmful sandblast dust. Because of its fragile molecular structure, non-recyclable media deteriorates quickly while generating harmful residual dust and substantially reducing operator visibility.

Although cost of steel-shot abrasive is about 10 times higher than non-recyclable media, steel shot can be recycled and used up to 100 times, compared to only once with standard media.

Abrasive Blast Room (ISTblast)

Welcome to our website: istsurface.com

We respect your privacy.

We use cookies to enable you to navigate efficiently and to optimize the functionality of the site. By clicking "Accept", you consent to our use of cookies. Failure to consent or withdrawing consent may have an adverse effect on certain features and functions.

"*" indicates required fields