What is an Abrasive Media Recovery System?

The abrasive media recovery system allows to collect residual abrasive media that remain on the floor after blasting operations, move it to a media reclaim system where dust and foreign particle matters are filtered out and diverted away to the dust collector, and only media in good working condition is returned back into the pressure blast pot.

The key advantage of the media reclaim system is to achieve substantial savings and protect our planet by considerably reducing our abrasive media consumption. According to the application and the type of media used, recycling rates of over 95% can be achieved.

Here is what you need to know about choosing the right media recovery system for your application.

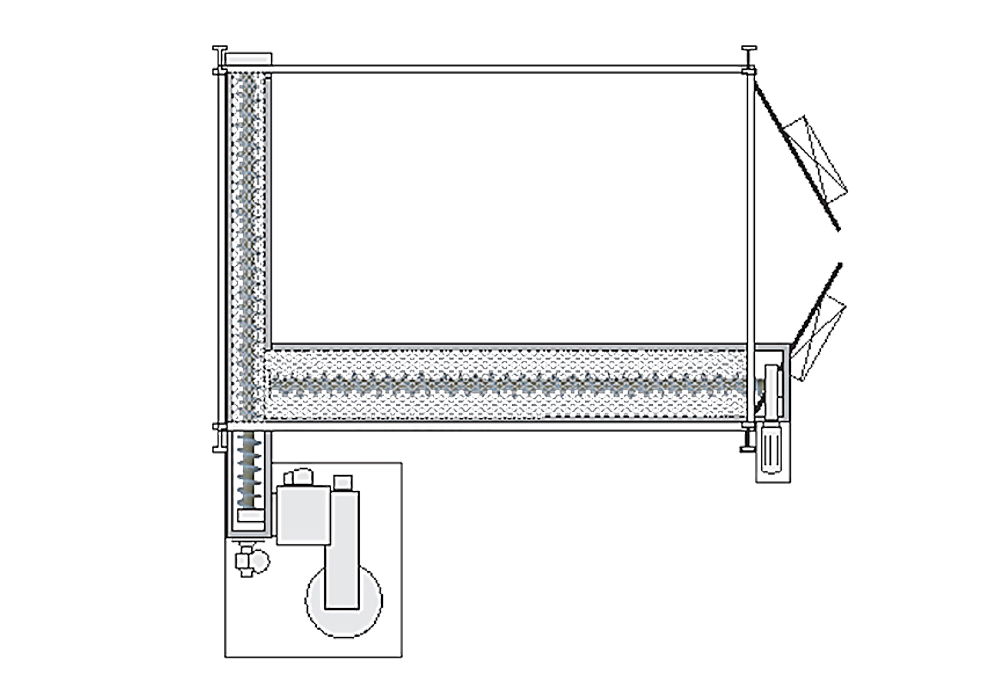

Floor Recovery Hoppers Installation

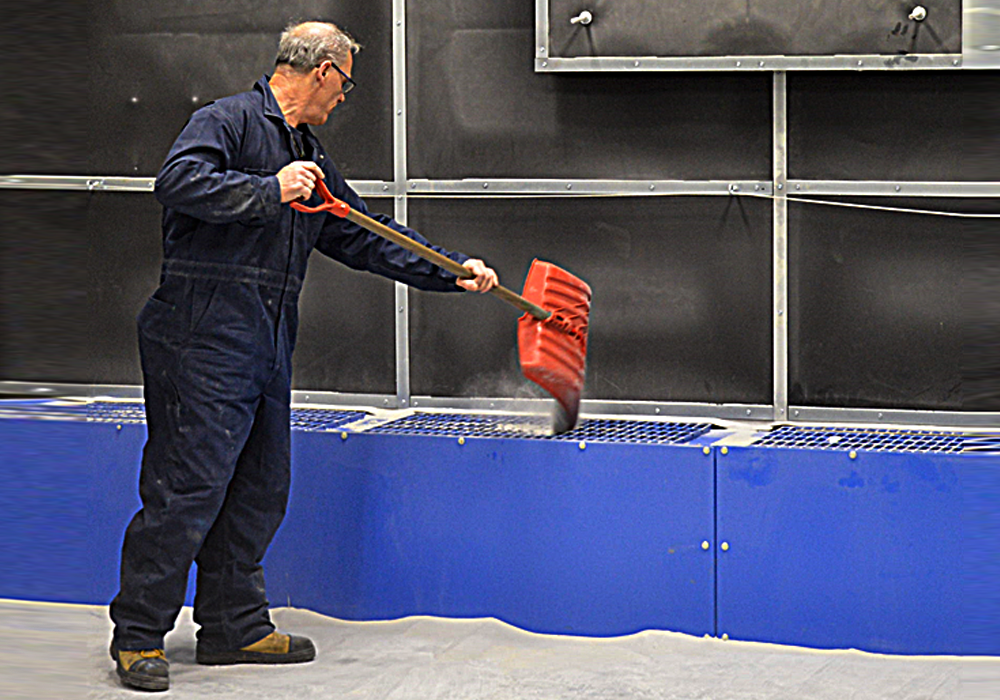

After blasting operations, used abrasive media must be swept or shoveled into recovery hoppers excavated into the floor or installed over the floor in surface installation.

Above or Inground Floor Hoppers?

Above floor installations don’t require any excavation. However, they require much more effort from the operator to shovel the blast media into the pit rather than simply pushing it into the excavated hoppers located below floor level.

|

|

| Above Ground Installation | Excavated Floor Installation |

Lengh of Floor Hoppers

Dimensions of recovery hoppers can vary from 10 feet in length for compact installations to over 200 feet for high throughput industrial blasting facilities.

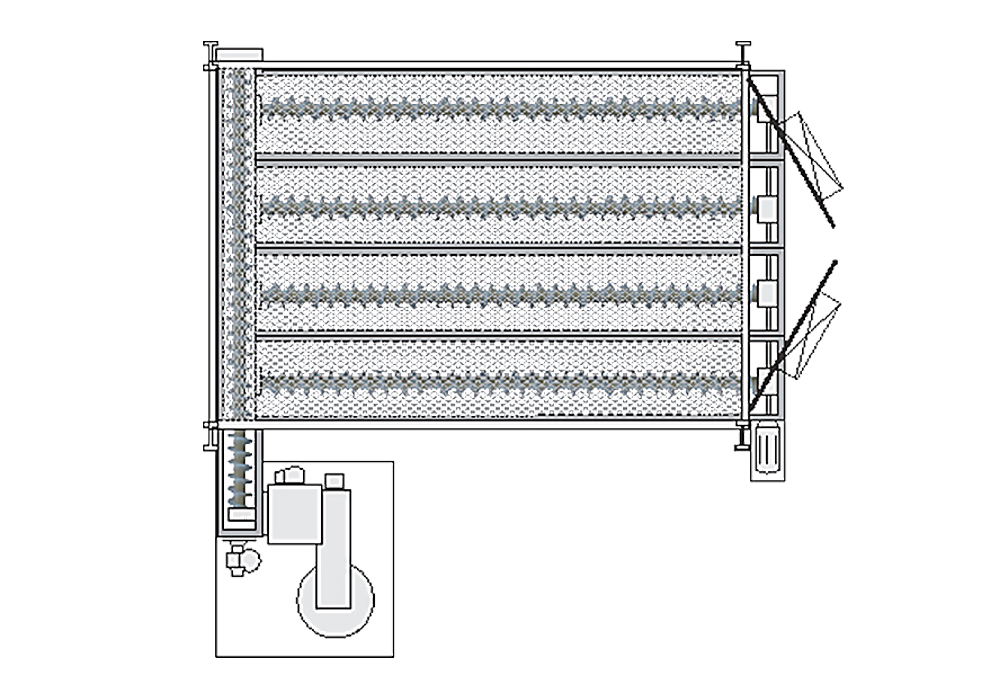

Removable Grating

Floor hoppers are protected by removable steel grating rated to 1,000 lbs per square foot. Other capacities are available to allow lift trucks and other materials handling equipment to circulate over it.

Floor Hoppers Coverage

Complete in-floor hoppers (excavation required) are more expensive, but they provide an automatic and continuous recycling of the blast media without the need to sweep manually. On the other hand, partial floor hoppers and corners require the operator to sweep the abrasive into the floor hopper.

So, What’s the Ideal Floor System?

Depending on your application, abrasive media, available production space, and budget constraints, there are various types of blast room recovery systems and floor layouts available.

In brief, here are the pros and cons of common layout options.

| INSTALLATION TYPES | PROS | CONS |

|---|---|---|

EXCAVATED FLOOR INSTALLATION |

|

|

ABOVE GROUND INSTALLATION |

|

|

FULL FLOOR COVERAGE |

|

|

PARTIAL FLOOR COVERAGE |

|

|

MECHANICAL LOADING WITH A BOBCAT |

|

|

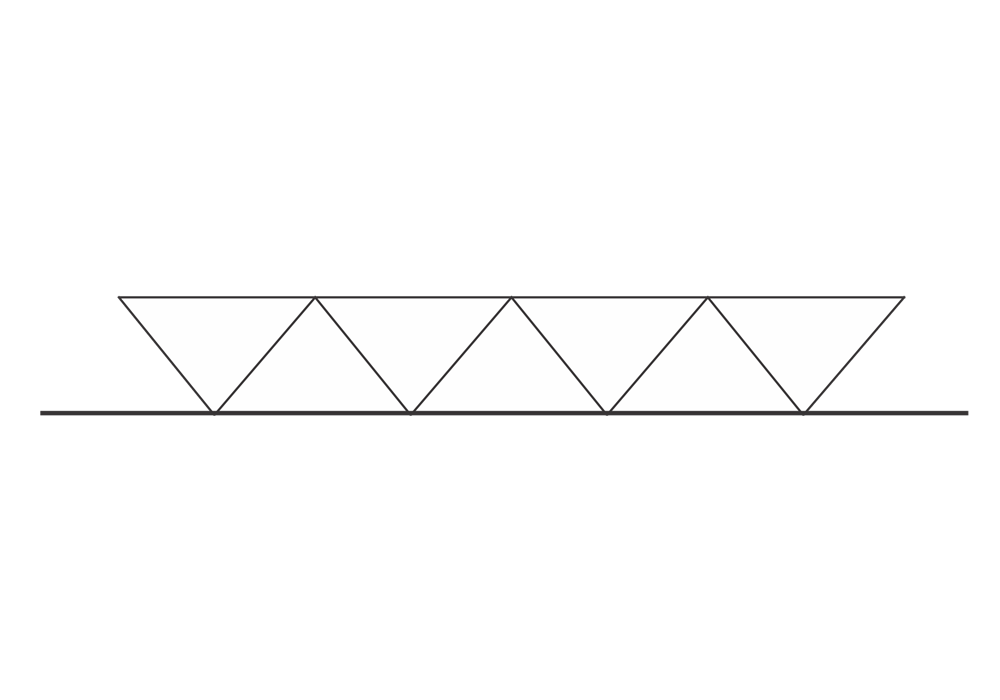

Media Recycling System

Once the blast media is collected, it is then moved to a media reclaiming system where dust, shattered media pieces, and other contaminants are removed, leaving only media in optimal working conditions. Depending on the application and the abrasive used, approximately 95% of the contaminated abrasive media mix will be recovered and returned to the pressure blast pot for further use.

Typically, ISTblast offers three standard Abrasive Media Recovery Systems.

| Type of Abrasive Recovery System | Mean to collect used abrasive media from the floor | Mechanical Separation of Media and Dust |

|---|---|---|

| Pneumatic | Urethane Suction Pipe | Cyclonic Separator |

| Mechanical | Screw Conveyor & Bucket Elevator | Air Wash |

| Hybrid | Screw Conveyor & Urethane Suction Pipe | Air Wash |

Pneumatic or Mechanical Abrasive Recovery System?

There are several factors to take into account when choosing the right abrasive media recovery system for your application.

- Your budget and estimated ROI: Mechanical recovery systems are more expensives to install, but they provide a more interesting return on investment (ROI) on the long term when considering overall costs associated with the operation and the maintenance of your blast booth;

- The objective of your sandblasting process: Surface preparation prior to coating versus blast cleaning for removing paint, rust, scale, etc.). Contaminants generated by your application is a significant factor to consider when evaluating between a pneumatic of a mechanical recovery system;

- The blast media required for your application: Heavy blast media – such as steel grit and steel shot – cannot be sucked in by a pneumatic recovery system;

- Your production space available in the shop: Pneumatic recovery system takes less floor space and require a lower ceiling height compared to mechanical recovery systems;

- Whether or not you are allowed to excavate in your building: Mechanical recovery systems require at least 5 feet excavation work;

- Many other factors: such as the recovery rate expected, the frequency at which you plan on cleaning your floor, whether or not your application generates combustible dusts that should be evacuated outside of the building, etc.

Here is a comparison chart of the main factors to be taken into account for making the right decision between a pneumatic, mechanical, or hybrid blast room recovery system.

| Abrasive Media Recovery System | |||

|---|---|---|---|

| Pneumatic | Mechanical | Hybrid | |

| Abrasive Media |

|

|

|

| Applications |

|

|

|

| Media Recycling Rate |

|

|

|

| Advantages |

|

|

|

| Limitations |

|

|

|