Sandblasting Booths

ISTblast Sandblast Booths provide the ideal confined environment for high-productivity sandblasting operations. Our custom engineered blast booths will exceed your expectations and reduce your production costs!

ISTblast Sandblast Booths provide the ideal confined environment for high-productivity sandblasting operations. Our custom engineered blast booths will exceed your expectations and reduce your production costs!

Home > Sandblasting Equipment > Sandblasting Booths

Turnkey Sandblasting Booth Project - IST designs, manufactures, installs, and maintains sandblasting booths across North America.

Enhanced Visibility - Lit by highly efficient LED lighting and equipped with a powerful dust collector to increase the sandblaster's visibility.

IST Care Preventive Maintenance Program (PMP) - The IST PMP will provide you with peace of mind that your system will operate under optimal conditions for 2 years following its installation.

Industrial-Grade Construction - Our sandblasting booth enclosures are built using high-grade galvanized steel panels and structural beams strong enough to support lifting equipment.

Comfort and Safety - We provide the most advanced safety and respiratory protection equipment for workers to reduce fatigue and the risk of injury when working over extended periods.

Code Compliance - We provide components approved by regional regulatory bodies and explosion-proof dust collectors that comply with NFPA standards.

Our modular sandblasting booth enclosure design is available in a variety of configurations to facilitate smooth personnel and product movement while maintaining the integrity of the walls.

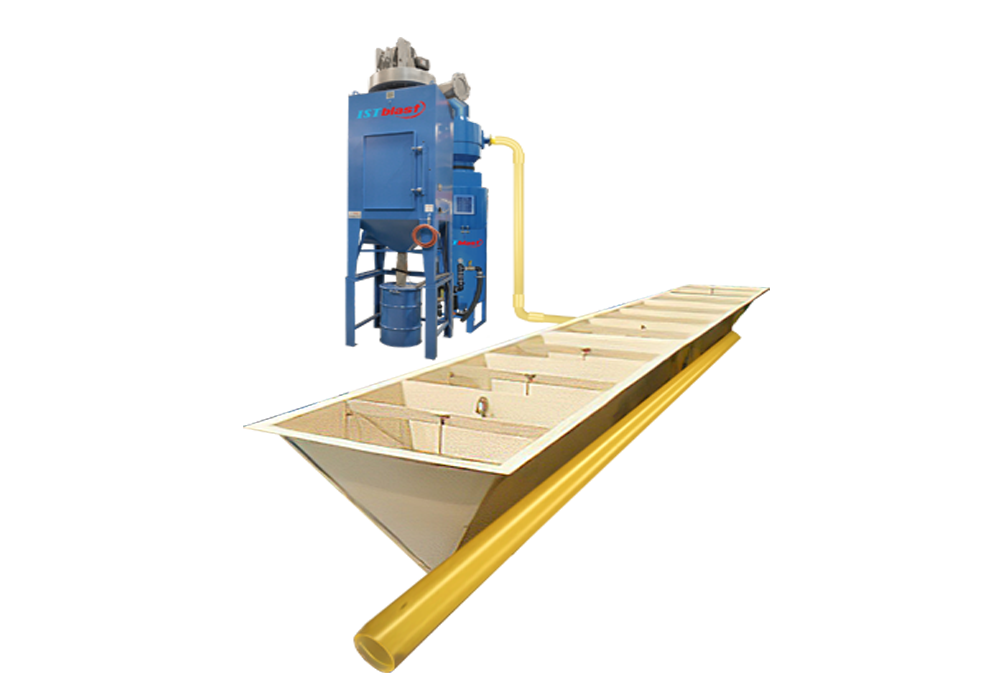

Choose from a range of pneumatic or mechanical abrasive media recovery systems to efficiently and economically recover media following sandblasting operations. Our solutions are suitable for both pit-installed and floor-mounted setups.

Our range of reverse pulse cartridge dust collectors can capture 99.9% of particles sized 5 µm or smaller. The cleaning process is fully automated to ensure a long cartridge lifespan.

Various combinations of pressure blasters and storage hoppers are available to ensure you never run out of abrasive during critical operations. Our blasters can supply up to 4 sandblasters simultaneously and can be operated from inside the booth to ensure uninterrupted productivity.

Our sandblasting booths are equipped with a high-efficiency Hi Bay LED lighting system with 18,000 lumens. Our unique design allows for easy installation, cleaning, and replacement of lights by a single technician from inside the booth. No need to climb onto the roof or involve two technicians to perform light replacements.

Whether you’re seeking a turnkey sandblasting booth solution or upgrading your sandblasting facilities by adding a media recovery system, ISTblast is your trusted partner with over 40 years of experience in industrial sandblasting.

Economical recovery system designed for light sandblasting installations.

Robust and reliable recovery system designed for heavy-duty sandblasting facilities.

Affordable system designed for small sandblasting booths and light applications.

A cost-effective and efficient system available in multiple floor configurations.

Vacuum head system designed to recover media from confined tanks.

An ultra-robust system capable of handling all types of materials and contaminants.

Ideal solutions for oversized chambers when excavation is not possible.

Complete line of dry and wet sandblasting cabinets designed for commercial and industrial use.

Complete line of pressure and blasters for job site contractors or indoor sandblast facilities.

Wide range of automated finishing systems to increase productivity and quality of products.

Welcome to our website: istsurface.com

We respect your privacy.

We use cookies to enable you to navigate efficiently and to optimize the functionality of the site. By clicking "Accept", you consent to our use of cookies. Failure to consent or withdrawing consent may have an adverse effect on certain features and functions.

"*" indicates required fields