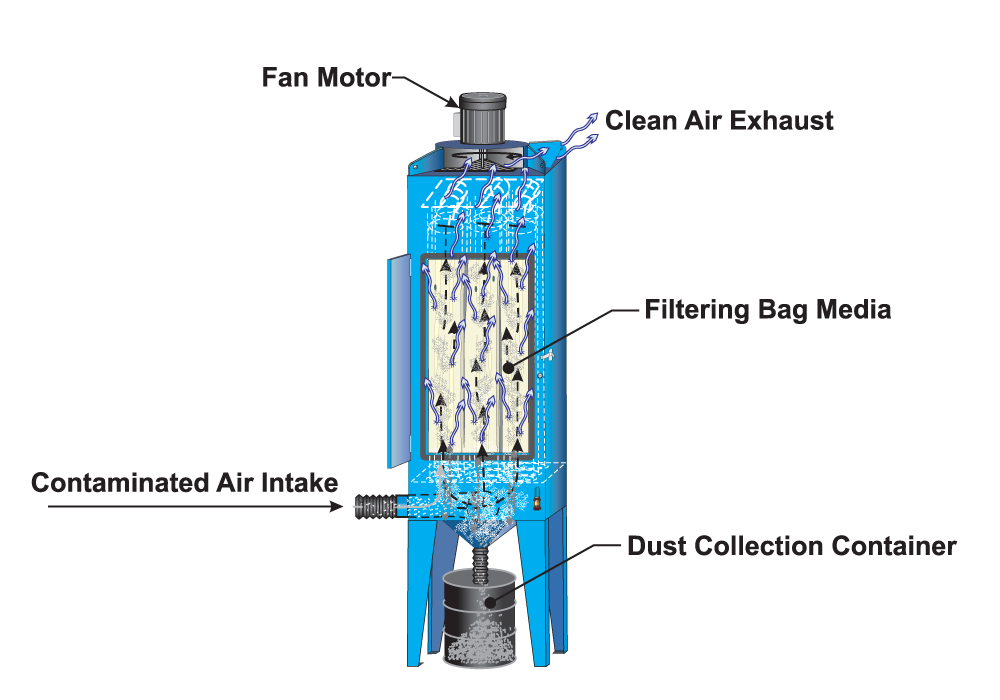

Bag-house dust collectors are a very effective and affordable system which can be used in a wide variety of sandblasting applications. Most sandblast cabinets today are operated with bag-house dust collectors because they perform well and are also cheaper to operate and maintain compared to cartridge-type dust collectors.

ISTblast’s bag-house dust collectors are available with different filtration capacities ranging from 50, 100, 160, 230, and 330 sq. ft. The size of the sandblasting area, the abrasive media used, and the level of contamination of the application will determine the requirements of the dust collector.

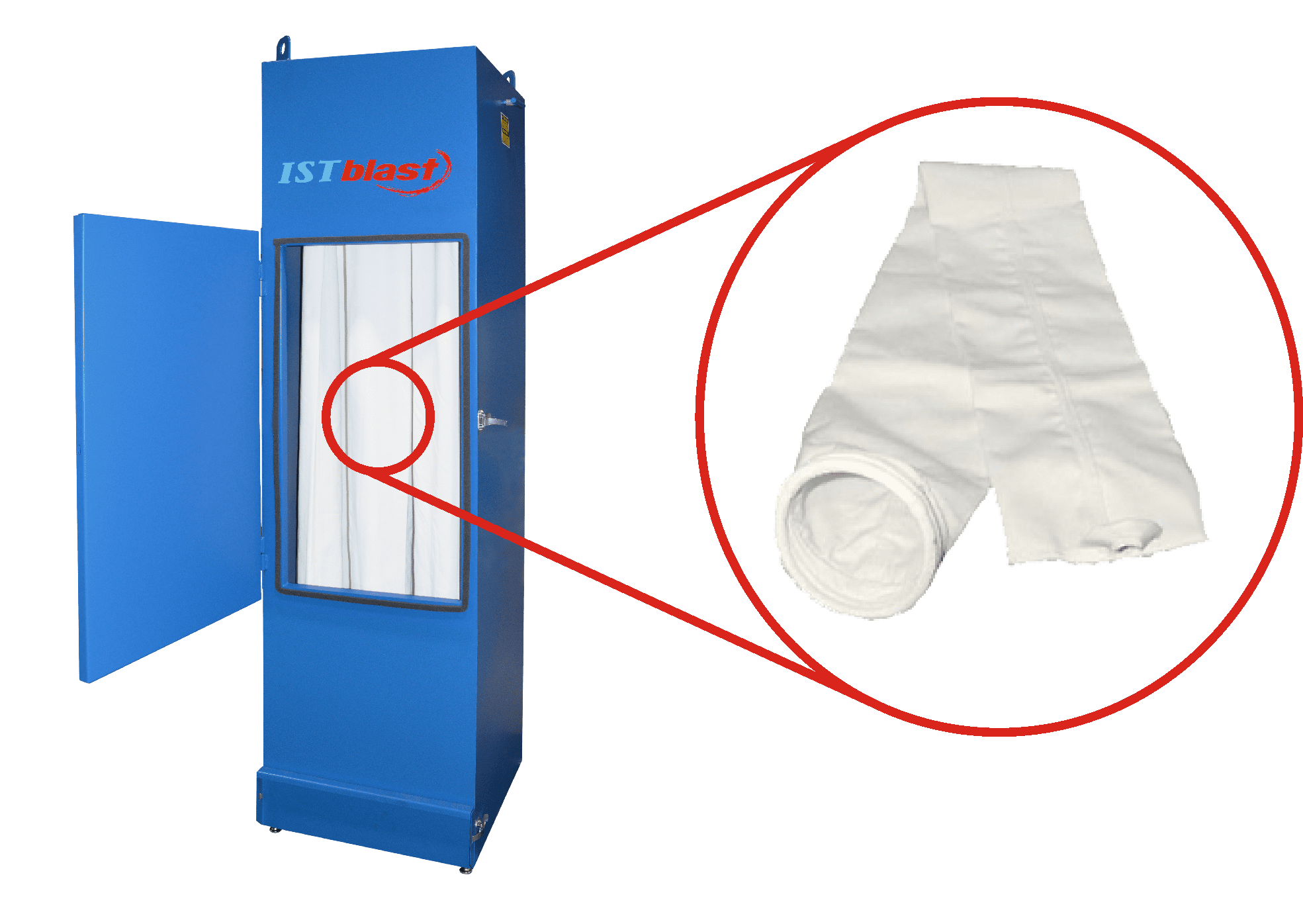

As its name suggests, the bag-house dust collector uses several filtering bags to capture dust and by-product contaminants. Once seasoned, our filter bags are capable of capturing up to 99% of particles down to 5 microns or over.

On bag-house dust collectors, the impeller can be located on either the dirty side or the clean side of the filtering bags.

How It Works

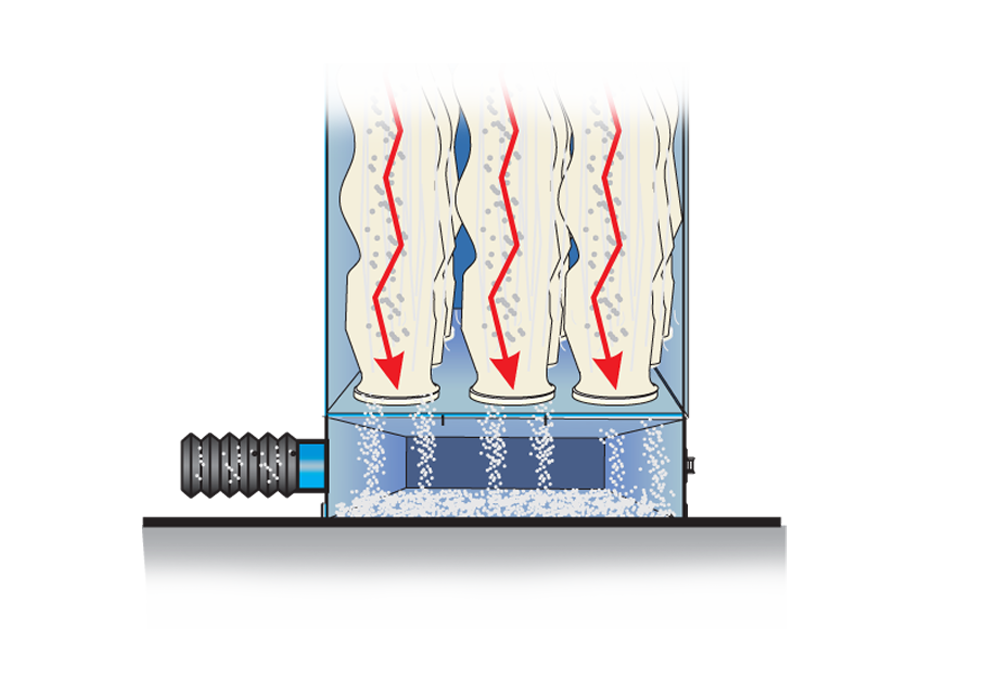

The principle of functioning is very simple. When the system starts, filtering bags (also called sleeves due to their rounded and narrow shape) inflate to maximize their filtration surface area and allow air to flow through their porous fabric.

As clean air is exhausted out of the filter bags, dust, process by-products (rust, paint chip, etc.), and other airborne contaminants are trapped inside the bags and will eventually fall to the bottom of the dust collector housing or in a dust barrel where they can be collected.

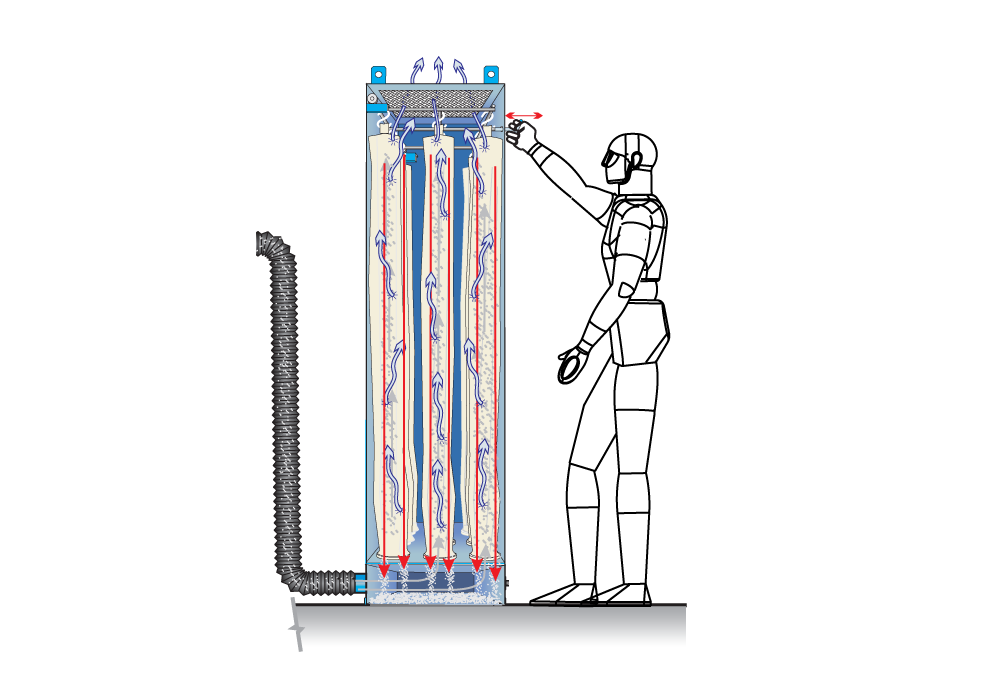

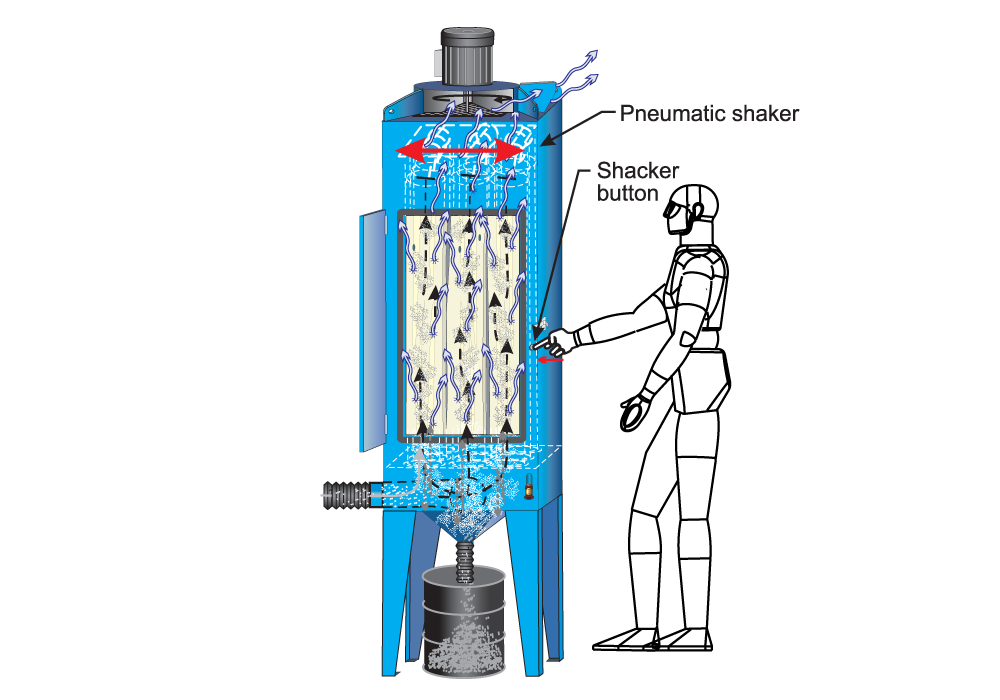

After each use, the filtering bags must be manually or mechanically shaken in order to release excess amounts of dust accumulated on their surface.

Maintenance of a Bag-House Dust Collector

Bag-house dust collectors are relatively easy to operate and maintain. Before and/or after each use, filtering bags must be shaken in order to dislodge dust build-up from their sides, and the dust collection container – normally located at the bottom of the dust collector’s hopper and actionable from a drain valve – must be emptied.

Some models are equipped with a sieve drawer which traps larger debris. The debris drawer must be emptied often to avoid clogging the air flow.

Filtering bags are easily replaceable when they stop performing as they should – when the system is unable to evacuate the dust cloud produced by the impact of the media onto the workpiece, or when the system is no longer able to move air normally.

The frequency of bag replacement depends on the application and how often the cabinet is used. In most cases, they need to be replaced every 4-6 years.

In order to extend their service life, filter bags should never be shaken while they are in use, washed in water, or be blown with compressed air.

Bag-House Dust Collector Cleaning System

To control dust buildup on the sidewalls of the filtering bags to an acceptable level, bags must be manually or mechanically shaken before or after each use in order to release excess amounts of dust from their surface.

IST offers three means to shake filtering bags:

1. Manual Shaking: The manual shaking system must be operated by manipulating a rod located on the side of the dust collector;

Standard on: DC50

2. Pneumatic Shaker with Push Button: The pneumatic shaker consists of an air-powered cylinder which moves on a horizontal axis when the operator presses a push button on the side of the unit;

Standard on: DC100, DCM100-330, and DCM200

3. Automatic Pneumatic Shaker: The automatic shaker operates using the same principle as the pneumatic shaker with a push button, except that the shaking sequence of the cylinder is triggered automatically when the sandblast system is turned off.

Optional on: DC100, DCM100-330, and DCM200

How to Properly Size your Bag-House Dust Collector

To ensure proper ventilation inside the sandblasting area, bag-house dust collectors must obtain a ratio of 6 CFM per 1 sq. ft. of filtration surface.

For instance, a 600 CFM impeller can efficiently move contaminated air through 100 sq. ft. of filtration surface.

A ratio above that mark will move air with too much velocity and result in prematurely wearing out the ventilation system, ducting, and filter bags.

A ratio below that mark will work fine during a very short period, but quickly lead to a dusty sandblasting zone, reduced visibility, and a need to change the filter bags more often.

The proper ventilation ratio involves two factors:

- Filtration surface area (sq. ft.) – The total filtration area is obtained by multiplying the number of filter bags with the surface area of one bag. The bigger the filtration surface area, the more efficient the filtration system will be, but it will also require a more powerful impeller to run properly.

- Fan motor (CFM) – The power required by the fan motor is determined by the filtration surface area (the number of filtering bags) of the duct collector in order to obtain a 6 CFM / 1 sq. ft. ratio.

When sizing the dust collector, we must also take into consideration any restrictions that can affect a proper airflow. The resistance that the air must overcome to reach its destination is usually measured in inches of water column (inch WC).

The length and diameter of the dust conveying hose, the presence of a cyclonic media recovery system, and the clogging condition of the sieve drawer are all factors which need to be considered in order to ensure a proper airflow.

The inch WC measurement is also used to determine the clogging condition of the filter bags, by comparing their initial inch WC value with the inch WC value after a few months/years of operation. However, most customers replace their filter bags when they no longer have clear visibility inside the sandblasting area.

Seasoning of Filter Media

Brand new filter bags must be ‘seasoned’ in order to function efficiently. In their original state, the bag’s pores are too wide to provide a proper filtration of small particles. For that reason, it is normal to see dust escaping from the dust collectors during the first few hours of operation.

When new cartridges are used, a small quantity of dust will stick to their sides and fill in their pores. The dust buildup will then create a thin layer of dust, which will actually act as a dust filter for further use. This process is known as the seasoning of the filter media.

By partially blocking the pores, dust buildup (also referred to as the ‘dust cake’) will contribute to the filtration efficiency of the system by capturing even smaller particles. Only then will the filter bags achieve their full potential.