- Equipment

- Abrasive

- Parts

- Services

- Industries

- Resources

- Videos

- About

- Contact

- FR

Home > Shop > Spray Equipment > Paint Spray Booths > Spray Booth

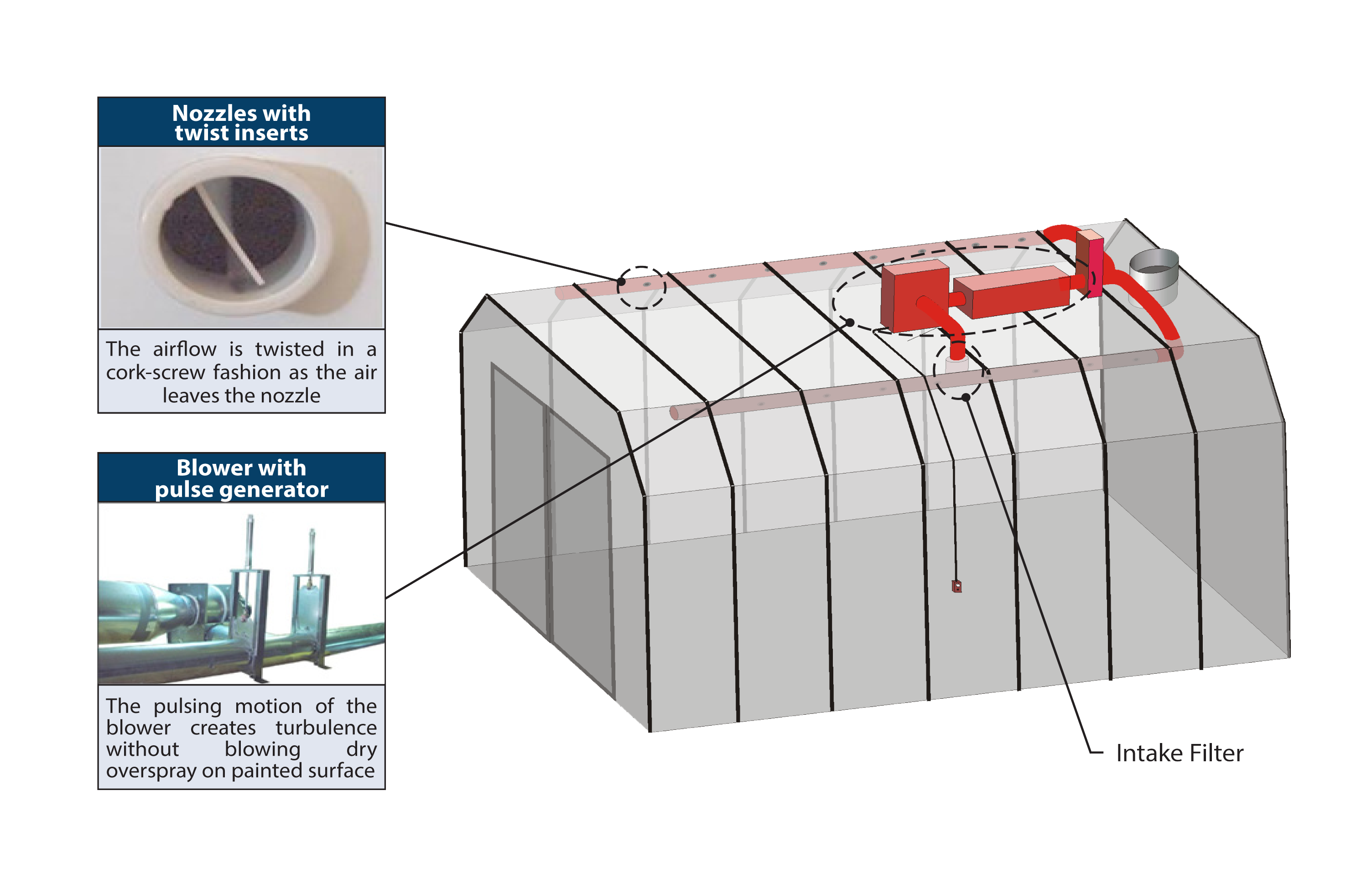

ISTpaint specializes in the engineering, manufacturing, installation, and servicing of custom-made Paint Booths, mixing rooms, and finishing systems of any sizes and configurations. Our systems are used in a variety of industries where high-quality finishing is required. Our spray booths provide a controlled environment for industrial surface preparation, painting, coating, and finishing applications.

Our paint booths can be designed with a filtration and exhaust system to provide a clean, ventilated source of air which keeps the spray chamber free of dust, fumes and overspray. According to the surrounding climate, an air makeup units (AMU) can provide temperature controlled fresh air for the booth in order to ensure an optimal curing environment.

All spray booth systems and components meet or exceed codes and compliance for CSA, OSHA, NFPA, ANSI, as well as most local building codes and fire codes. A system certification can be obtained upon request.

|

Canadian Standards Association |

|

Occupational Safety and Health Administration |

| National Fire Protection Association | |

| American National Standards Institute |

Booth Features

Crossdraft booths, the simplest configuration, are efficient and economical, and best suited for coating industrial/ large equipment, truck, and wood applications.

ISTpaint crossdraft spray boots take in fresh air through filters in the product doors. The clean, filtered air is drawn through the booth and exhausted through a filter system at the opposite end.

How It Works

Offering a clean and healthy work place, modified downdraft spray booths allow for easy pressurization with the addition of an intake plenum with a fan or a heated air makeup unit. The modified downdraft takes in air from the cleaner upper levels of the shop through a filter bank located in the booth’s ceiling, near the product doors.

The filtered air is drawn down through the booth to an exhaust filter system at the other end, and is optionally equipped with a pre-filter plenum for additional intake air filtration.

How It Works

A more economical solution for shops that are unable to install a pit, side downdraft spray booths take in fresh air from the cleaner upper levels of the shop through a filtered booth ceiling. The filtered air is drawn down and away from the product through exhaust filters at the floor level along both sides. This provides efficient overspray control that reduces prep time while also delivering a healthier work place environment.

The side downdraft booths can also be purchased with a pre-filtered plenum or a pressurized intake plenum, and can be equipped with an air replacement unit and cure cycle to meet your requirements.

How It Works

Providing the best airflow style, downdraft booths offer efficient overspray control which reduces prep time and also provides a much healthier workplace environment. Downdraft booths take in fresh air from the cleaner upper levels of the shop through a filtered booth ceiling. The filtered air is drawn down and away from the product, into the filtered exhaust pit located in the floor.

This booth can be purchased with a pre-filtered plenum or with a pressurized intake plenum. It can also be equipped with an air replacement unit and cure cycle to meet your requirements. An optional above ground basement exhaust plenum is available for installation without concrete work.

How It Works

IST provides a wide range of equipment for the upkeep of a spray booth or to manage waste material generated from industrial coating processes.

|

|

| Air Makeup Unit (AMU) | Drying room |

|

|

| Waterborne Paint Drying System | Mixing Room |

|

|

| Solvent Recycling System |

Welcome to our website: istsurface.com

We respect your privacy.

We use cookies to enable you to navigate efficiently and to optimize the functionality of the site. By clicking "Accept", you consent to our use of cookies. Failure to consent or withdrawing consent may have an adverse effect on certain features and functions.

"*" indicates required fields